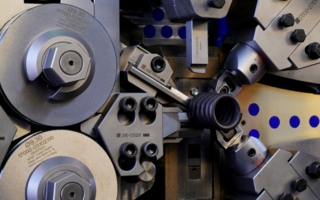

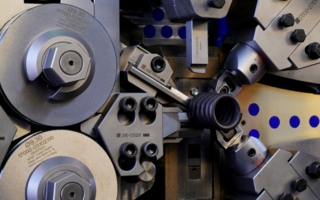

The system allows customers to quickly change the cutting method according to the characteristics of the spring to be produced: linear, rotary, fly and torsion. © OMD

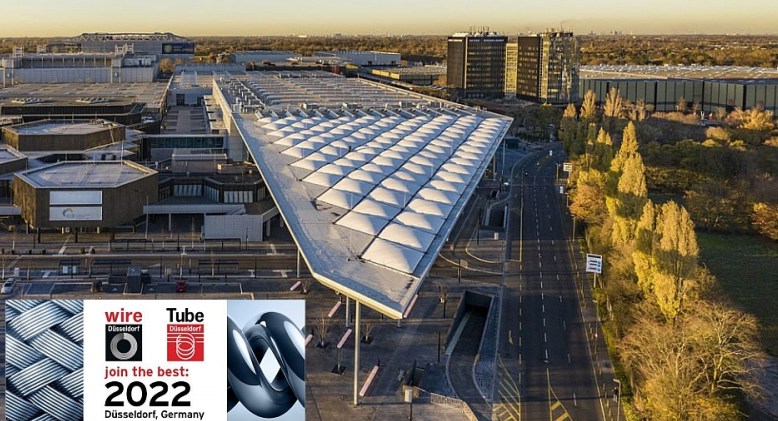

At last, ‘wire’ is back again

Four long years without "wire" are over. From June 20 to 24, the trade fair was again held together with ‘Tube’ this year supplemented by ‘Metav’. Our complete coverage with all relevant trade show news of the industries can be found here bundled on this "wire 2022" page.

Photo: Messe Düsseldorf

The system allows customers to quickly change the cutting method according to the characteristics of the spring to be produced: linear, rotary, fly and torsion. © OMD

“wire” 2022 presented 1,057 exhibitors from 51 countries on some 53,000 square metres of net exhibition space. © Messe Düsseldorf

Cimteq’s “Cable Builder Enterprise” and Aesa Cortaillod’s quality management software, “CIQ”, present a unified cable testing solution from product design direct to cable testing equipment. © Cimteq

Manfisa draws pure aluminium and aluminium alloys in a variety of diameters from 0.75mm to 13.50mm. © Manfisa

In 2021, Cersa MCI released its solution for wire and cable surface defect detection: the SQM. © Cersa MCI

CuCrZr and CuCrAgSi alloys can be drawn to extreme fine wires, of up to 0.025mm, that remain strong and very flexible. © Lamifil

With a reverse osmosis concentration unit, it is in fact today possible to concentrate back the dragged solution producing demineralized water. © Condoroil

Wardwell invites customers to see the latest version of this popular unit: the “Speedmaster 2M”. © Wardwell

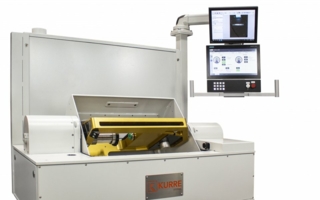

The Kurre braid winder perfectly winds ultra-fine wires from 0.05mm and prepares them for the braiding process. © Kurre

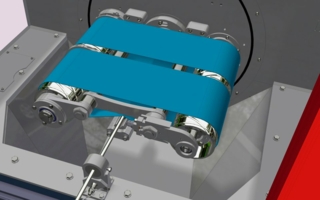

The pull-in gripper moving by a ball screw is pulling in the wire, which is then taken over by the chaintrack drawing system. © EJP Maschinen

The SMS booth at the Tube and wire trade fair, hall 7, booth B 04, covers an area of 400m2. © SMS Group

Visitors to “wire” are already securing meetings with Cimteq to view demonstrations of all products. © Cimteq

Straightening machine “RA 7-15 H PO” with revolutionary technical solutions for quick opening/closing, individual and defined roller adjustment plus the toolless quick roller change. © Witels-Albert

Foerster has developed the optical documentation system “Defectoview HS” to supplement the eddy current testing. . © Institut Dr. Foerster

The “JET Rapid Wire PI” in use at cable manufacturer Huber+Suhner from Pfäffikon in Switzerland. © Leibinger

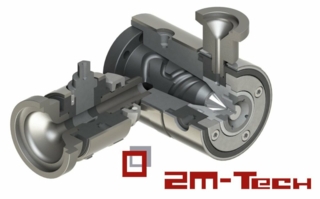

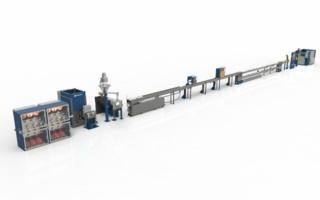

2M-Tech supplies crossheads and complete extrusion coating lines for special applications. © 2M-Tech

The “wire” trails guide participants to Netzwerkdraht, Rosendahl-Nextrom, Swiss Steel Holding GmbH, Aurubis and Arcelor Mittal. © Messe Düsseldorf

The new grinding descaler achieves the same grinding performance as previous double-head machines, however with a much simpler design. © EJP Wire Technology

The “E-Flex“ offers complete freedom in the coil production of objects of any type, in an extremely fast and repeatable manner. © BLM Group

“e phos”-Off-line device with a 4-t-spooler for the production of phosphate steel wires. © Staku-Anlagenbau

Specialized in tension-sensitive winding materials – the new taping machine from Kurre Systems. © Kurre

20 specialist companies are available to provide ideal technical solutions for the wire and cable production worldwide. © AWCMA

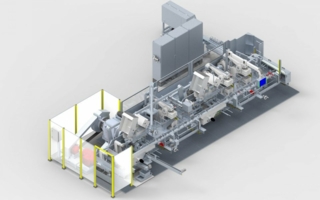

A large volume of test cables was produced using Rosendahl’s RM-A line under real manufacturing conditions. ©

Suzuki Garphyttan is now investing heavily in development and making significant investments in all production facilities in order to be able to offer high-quality products in more product areas, for example in forming and annealing. © Suzuki Garphyttan

Pressure Welding Machines will exhibit its full range of high-performance cold welders, including the best-selling “EP500” rod welder. © PWM

Condat offers borax free dry drawing lubricants, which in some cases, even demonstrate increased performance over traditional borax containing products. © Condat

With “COM CNC” line Fortuna has reached potential of delivering custom made solution for large mass production. © Fortuna Federn

SAS Engineering+ Planning is specialised in the manufacturing of equipment for cold finishing. © SAS

High-speed automatic spring coiling machine “MT15”, fitted with the latest generation multi-axis numerical control. © Simplex Rapid

AWI will introduce “Inconel: 617”, a nickel-chromium-cobalt-molybdenum-aluminium alloy. © Alloy Wire International

Maillefer present an Artificial Intelligence (AI) based process assistant, “Smart Buffering”, which operates on top of the process automation layer. © Maillefer

The entire Düsseldorf Fairgrounds and Congress Centre will have been fitted with 3,000 HEPA filters by the time wire and Tube, are held from 20 – 24 June. © Messe Düsseldorf

Pan Chemicals producing drawing lubricants, coatings and chemicals for the wire Industry. © Pan Chemicals

At this stage 1,000 companies from 47 countries have already registered for wire 2022. They occupy 53,210 square metres of net exhibition space. © Messe Düsseldorf

At this stage 1,000 companies from 47 countries have already registered for wire 2022. They occupy 53,210 square metres of net exhibition space. © Messe Düsseldorf

Whether thin signal cables, standard data cables or thicker battery cables, – the “Centerview 8000” is a true all-rounder. © Sikora

“MCV4”: The most efficient machine for 360° dimensional inspection combined with crack detection and heat treatment control. © Dimac

Resibed unit for continuous regeneration of 1,000l/h of sulphuric-hydrofluoric solution. © Condoroil

Battery and portable shears, provided with a 360° rotating head, engineered for both wire and cable. © Tramev

The new all-in-one machine developed by Amba is the first in the world to produce up to 420-mm-long full-thread screws in one continuous process directly from the wire coil. © Aachener Maschinenbau

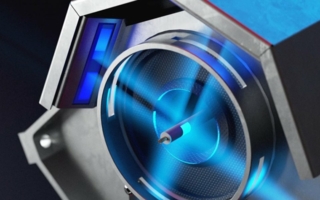

“SQM” is an equipment capable of detecting defects that may appear on the surface during the drawing or extrusion process. © Cersa MCI