03/06/2022 – Surface treatment

Advanced wire grinding descalers

EJP Wire Technology GmbH, EJP Italmec Sp. z o.o. and WWM Technology srl have recently joined their forces under the umbrella of EJP Industries. The three companies will now be spotlighting their latest innovations together at the “wire“ trade show. Highlights will be a new wire grinding descaler and the latest generation of cleaning and copper coating units for welding wire production.

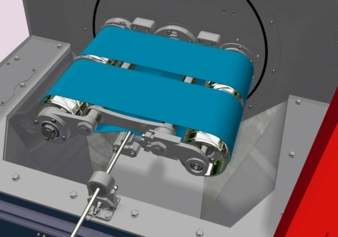

At the trade fair, EJP Wire Technology will be showcasing its latest, fully redesigned version of the “SA-2” grinding descaler. In contrast to the previous design, the new machine operates with just one rotating head, which can accommodate two grinding belts with different types of abrasive grains – for rough and fine grinding, for example. The machine achieves the same performance as the previous double-head units, however with a much simpler design.

Lothar Köppen, Managing Partner of EJP Wire Technology GmbH, has been active in this business since 2004 and is therefore familiar with the technology and the wire production world: “In the new machine we have just one rotating grinding head. This arrangement allows us to guarantee a uniform and consistent wire surface quality, even though we are using two grinding belts. The complicated process of synchronizing the belt speed with the wire speed has become a thing of the past. The good thing for the customer: something that does not exist, can’t cause any trouble.”

WWM will be showing its latest generation of cleaning and copper-coating units for welding wire production. With these new systems, based on the concept of chemical coppering, the process speed can be increased from 15m/s to 30m/s while assuring the same high product quality. The coating units can be combined with dry and wet-drawing machines, such as the slip-free wet-drawing machine that WWM Technology presented at the previous edition of “wire”. EJP Italmec will be displaying its range of machines for the production of low-, medium- and high-carbon wire.

Three of EJP Industries’ group companies specialize in machinery and systems for the production and processing of wire:

– EJP Wire Technology based in Schwerte/Germany: Wire pretreatment systems

– EJP Italmec based in Katowice/Poland: Production equipment for low-, medium- and high-carbon wire

– WWM Technology based in Conselve/Italy: Production equipment for welding wire

This setup makes EJP one of a select few of manufacturers able to serve the entire wire production chain with advanced systems, and its customers around the world with a global sales and service network.

wire 2022, hall 11 booth D 06, hall 9 booth A 12

EJP Wire Technology GmbH

Lohbachstrasse 12, 58239 Schwerte/Germany

Contact person is Lothar Köppen

Tel.: +49 2304 338960

l.koeppen@ejpwire.com