12/05/2022 – Continuous kneaders

X-Compound upgraded its Customer and Application Centre

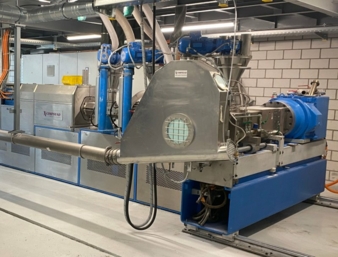

X-Compound, one of the worldwide leading manufacturers of Continuous Kneaders, upgraded its Customer and Application Centre in Kaisten, Switzerland.

The heart-piece of the Application Centre is a pilot scale Continuous Kneader “CK100”. This line is available to evaluate X-Compound’s technology for demanding and complex compounding processes. Especially when it comes to temperature sensitive, shear sensitive, or highly filled compounds, Continuous Kneaders show distinctive advantages. The Application Centre is equipped with a complete and full automated upstream and downstream material handling and pelletizing equipment. With a flexible and intelligent setup, X-Compound’s partners have the opportunity not only to evaluate the advantageous technology but also to produce large quantity samples for further analysis or production steps.

“The Application Centre is an essential part of X-Compound’s strategy to inspire our customers and to develop intelligent solutions together with our customers.” states Raul Friedrich, General Manager of X-Compound. Peter Schmidt, CEO of Troester adds “The created possibilities will allow X-Compound’s customer to experience the advantages of our technology.”

Companies interested in the manifold possibilities of Continuous Kneaders technology are invited to visit the facility and to evaluate the technology.

X-Compound GmbH

wire 2022, hall 10 booth F 60

Tel: +41 62 869-1014

www.x-compound.com

About X-Compound

X-Compound GmbH in Kaisten/Switzerland produces Continuous Kneaders. The company was founded 1997 and evolved into a worldwide leading manufacturer of Continuous Kneaders. The company was acquired in 2011 by the Troester Group located in Hannover. X-Compound offers a broad range of machines and entire Compounding plants. The core of all plants is the Continuous Kneader. With only a minimum energy input, the machine can achieve superior mixing performances. The unique mixing principle makes it possible to control exactly the material temperature. This makes this technology ideal especially for temperature sensitive materials.