21/05/2022 – Automation: Uhing Motion Rolling Ring Drive

Faster processes, high precision

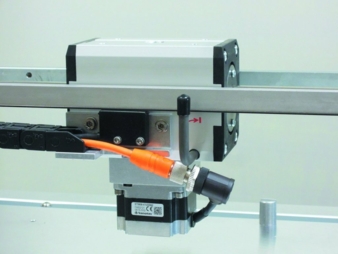

Uhing combines the robust and reliable rolling ring drive technology with a stepping motor connected to a Siemens “S7 PLC” controlling the pitch setting and the reversal. The degree of automation can be increased by implementing displacement transducers and sensors to meet individual requirements.

Uhing rolling ring drives are a real alternative to drives based on timing belts and threaded spindles whenever a permanent reciprocating movement is required during production and operation. Applying automated solutions, the specialists also help to develop prospective processes of high efficiency and quality.

“The non-positive drive translates the movement of a rotating plain shaft with constant speed and direction of rotation into a stroke movement of the rolling ring drive”, Wolfgang Weber, Uhing’s Managing Director points out the basic principle of the rolling ring drive. Speed and stroke length are flexibly adjusted via the pitch values. The integrated reversing mechanism with adjustable stop ensures highly dynamic stroke reversal.

The company’s engineers have been constantly developing the basic idea since it was invented by the company’s founder in 1952. “Uhing ‘Motion Drive’ is one of our automated solutions for perfect winding patterns and smooth processes,” Weber exemplifies.

The system features an easy to operate touch panel where parameters for speed, action and reversal points as well as stroke lengths can be specified and controlled. In addition to the comprehensive standard programme, the user can also press a button to choose the material and the spool type and store custom winding patterns and material combinations in order to significantly speed up conversion processes. Perfectly matched sensors and control unit are the key to precise implementation and automatic readjustment.

“Motion Drive saves time and warrants a constantly high quality”, emphasises Weber and gives an example: “Rewinding wires and metallic ribbons from large to small convenient spools involves many spool change actions. Although the spools are of the same type, they are not entirely identical. Before, a customer had to insert a new spool and individually set up the mechanic reversal points. Today, the Motion Drive adjusts itself and starts the pre-set winding process once the customer has inserted the spool. The desired winding patterns are generated without manual intervention.”

High flexibility, numerous applications

The system’s enormous flexibility allows for a great number of applications, from coating, inserting or handling in the automotive industry, cleaning, separating, spraying and distributing in the food industry, or opening and closing, positioning, indexing, chaining or winding in the packaging industry. In addition to Uhing Motion Drive, the company offers other automation solutions to be considered during the design phase or which can be retrofitted:

– Uhing Measuring System (UMS)

Combined with a pneumatic reversal mechanism, laser sensors identify the spool flanges and trigger the stroke reversal.

– Uhing Moveable Endstops (UME)

Controlled by stepping motors, the limit stops on each side can be individually matched to the application. For example: Winding of bi-conical spools, winding of trapezes (negatively bi-conical), etc.

– Uhing Modular Winder (UMW)

This is a modular rewinding unit that to some extent can be matched to the customer’s requirements. As traversing unit, the classical Uhing rolling ring drive can be used, but also the “UMD”.

wire 2022, hall 11 booth B 40

Joachim Uhing GmbH+Co. KG

Konrad-Zuse-Ring 20

24220 Flintbek, Germany

Contact person is Wolfgang Weber

Tel.: +49 4347 906-0

weber@uhing.com

www.uhing.com