17/06/2022 – Eder Engineering-Austria celebrate their 75th anniversary

Initial goal has remained unchanged

Eder Engineering-Austria, founded in 1947, are proud to celebrate their 75th anniversary in 2022 and since have been pioneers and technology leaders in supplying the international wire and cable industry with many then new and outstanding products and technologies.

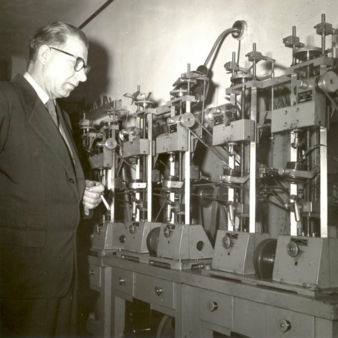

Siegfried Eder, then a key technical manager of a large wire and cable manufacturing plant in Vienna, founded Eder Engineering in Vienna/Austria in January 1947. It started with the production of tungsten carbide drawing die tools, later included natural diamond, then involving designing and making die processing equipment too. So soon after the end of WW2, all these products were needed everywhere and considerable expansion in both the production scope and exports abroad took place, at first in neighbouring countries such as Germany, Hungary, Yugoslavia etc.

“The then prevailing production scope was about 80 per cent die tools, 15 per cent machines and 5 per cent technical assistance.” The company then reached a pioneering position in the late 1960s, after the founder´s son, Dr. Kurt Eder, managed to produce the first Compax/PCD drawing die-tools and with a specifically designed new line of more powerful equipment.

Thereafter, Eder-Austria soon shifted its portfolio to mainly making advanced die-tool working machines and software. Today, Eder Engineering, with about 98 per cent export quota, satisfies regular customers in more than 80 countries, offering semi and fully automatic concepts for the production and/or reconditioning of ultra-hard precision die tools made from tungsten carbide, natural diamond and synthetic PCD.

The reconditioning of drawing dies on a regular basis is essential to the production of consistent high-quality wire. As nowadays, tens of thousands of costly diamond/PCD die tools are in permanent use in wire drawing mills and cable plants, particularly in multi-wire drawing operations,” a high degree of these machines´ automation is requested and today plays a very important role in keeping die-repairing costs low, making all operations easily performed and limiting the intervention of human personnel.

Dr. Eder’s insistence on innovation has kept the company at the forefront. “The requirements of the wire and cable industry worldwide keep changing and it is crucial for us to reinvent the wheel all the time,” he says. The next generation of the Eder family already is standing by to continue the success of 75 years serving the international wire and cable industry at its best and mainly with technical advanced die-tool processing equipment. The initial goal has remained unchanged: fully satisfied customers.

wire 2022, hall 10 booth C 42-01

Eder Engineering GmbH

Peter-Jordan-Strasse 12/3, 1190 Vienna, Austria

Contact person is Dr. Kurt G. Eder

Tel.: +43 1 3674949-13

kurt.eder@eder-eng.com

www.eder-eng.com