13/05/2022 – Quality management

Wire surface quality checks

In the publication „A holistic view of the in-line linear wire cleaning“ Geo-Reinigungstechnik presented and compared the cleaning potential of various mechanical and aqueous processes based on their many years of experience in cleaning wire and profile surfaces. But how is the surface quality determined before and after processing? Which procedures are used?

The wipe test is a frequently used method for testing the surface quality of wires before and after processing, such as wire cleaning. This involves the wiping of a wire section with mostly white paper, which is pressed against the running wire surface with the fingers or the back of the hand for a few seconds. The test can be carried out quickly and easily, and usually allows a simple visual assessment of the cleaning result by means of a "before and after" comparison of the residues in the cloth caused by the wiping.

However, ensuring that all parameters are the same, for an objectively comparable test, is not so simple. The cloth or paper used can vary in structure and in terms of abrasiveness. Even if the test is carried out by only one person, the finger pressure is not constant, and often stronger than necessary. To wipe off contamination, it is usually only necessary to gently touch the wire/profile surface with the paper.

Paper and smoke test device

The PTD (paper test device) is a handy tool for performing “tissue tests”'. Working with the PTD ensures that the wiping always takes place under the same conditions (force and contact surface) and that the results are objectively comparable. Matching, waterproof paper strips (PSW 1840) facilitate handling. Use of a microscope is recommended, to analyse the traces of abrasion.

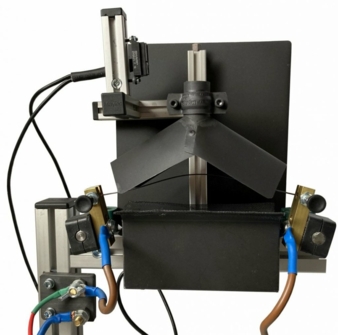

Another method for assessing the cleanliness of wires before and after cleaning is the “smoke test” for the visual determination of hydrocarbons. Geo's STD (smoke test device) is used for the comparative measurement of hydrocarbon quantities on wire surfaces (with a testable wire diameter range of 0.5mm to 3mm). For this purpose, a wire section is clamped between two contacts in the device and heated until it glows by applying a corresponding current strength. The resulting amount of smoke corresponds to the amount of hydrocarbons that were previously on the surface as pollution. The amount of smoke can be determined both visually and quantitatively using a sensor and data logger.

The STD measuring device is a ready-to-use system with an integrated data logger and USB interface. The software and drivers are supplied on USB stick or CD, and are installed on a PC (compatible with Windows 7 to 10) before the system is started up. The licence-free software can be used on multiple computers.

Measuring equipment for quality assurance and systems for wire coating complete the program for manufacturers and suppliers of welding wires and other wire products.

wire 2022, hall 11 booth A 32

Geo-Reinigungstechnik GmbH

Im Garbrock 7, 48683 Ahaus-Ottenstein/Germany

Tel.: +49 2542 9555290

info@geo-reinigungstechnik.de

www.geo-reinigungstechnik.de