13/06/2022 – From Turkey

Braiding and taping machines and cable raw materials

Operating on the cable market since 1981, Gurfil (Istanbul Turkey) has established itself as a reliable supplier of Braiding and Taping machines, as well as a cable raw materials manufacturer.

On the one hand, the growth of the cable industry in Turkey at a continuous pace in the context of the growing urbanization and developing infrastructure of the country, and on the other hand, the increase in production capacity through constant investment in modern technologies; all these allowed the company to cover a larger share of the domestic market and enter the international market.

Today, Gurfil can say with confidence that there is practically not a single cable plant where Gurfil products are not known. They are trusted by the largest cable manufacturers around the world, including Germany. It is worth to mention that Gurfil is an honorary member of the International Wire and Machinery Manufacturers Association (IWMA), the main partner of Messe Dusseldorf GmbH, organizer of the largest exhibition of the wire industry.

Based on 40 years of experience and on the results of their own technological developments, Gurfil present equipment and technologies for the cable industry to the market, supplying not just machines, but developing complex technological solutions designed to meet production needs, ranging from cable holdings to small businesses.

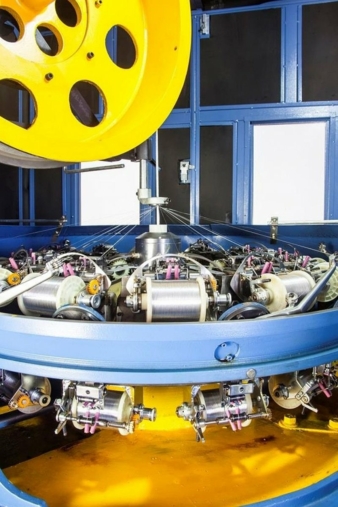

Today they focus on modern high-performance equipment: horizontal braiding machines, vertical taping machines, which allow producing cables that meet all safety requirements. Gurfil specializes in the following lines and their modifications for the production of cable and wire products:

– High-speed vertical braiding machines (16 and 24 bobbins);

– High-speed horizontal braiding machines (24,32,36,48 bobbins);

– Mica Taping Machine (1, 2 and 3 heads, can operate with pads and spools);

– Wire rewinding line (semi and fully automatic);

– Pay-Off and Take-Up;

– Spare parts for all equipment.

The indisputable advantages of using vertical taping machines for the application of fire-resistant mica tape allow cable manufacturers to increase significantly their productivity and produce reliable and safe cable: fully synchronized, easy to maintain and require minimal operator attention; operates with an extended range of materials: Mica tape, ALU/PET film, PET film etc.; taping unite speed up to 2500 rpm.

Increasing exports to the German market is a priority for us in 2022 as well. Therefore, we offer favorable conditions to our customers. A well-developed logistics system between Germany and Turkey allows for door-to-door delivery in the shortest possible time.

Along with the equipment, Gurfil supplies cable manufactures with flexible cable raw materials such as foil, film, or tape.

Continuous orders from their established partners (buyers of our equipment, as well as foil- films-tape) are the most convincing argument for customers choice in favor of Gurfil equipment and raw materials. Gurfil hope that 2022 will be more successful and favorable for all and for cable industry in general.

wire 2022, hall 9 booth A 74

Gurfil Foil-Film-Tape+Machinery A.S.

Osman Gazi Mah. 3130. Sok. No: 6/2,

34522 Esenyurt/Istanbul, Turkey

Tel.: +90 212 8868618

info@gurfil.com

www.gurfil.com

Cable raw materials

– Mica Tape (phlogopite, phlogopite with silicone backing, muscovite and synthetic);

– ALU/PET, ALU/PET/ALU, ALU/PET/SY, ALU/COPOLY laminates;

– CU/PET, CU/PET/SY laminates;

– Polyester film;

– Foamed PP tape;

– Kraft paper and crepe paper;

– PP Identification tape;

– Fiberglass tape;

– Semi conductive tape and swellable tape;

– Fleece, Bedding, TNT tape;

– Non-Conductive Polyester non-woven tape;

– Rip cord yarn;

– Fiberglass yarn;

– Water-blocking threads - available from stock.

http://www.gurfil.com