30/05/2022 – Modern inline procedures redundantize traditional pickling processes

Technology for CHQ production

Since the invention of the electro phosphating process “e phos” in 1998, we have experienced significant world-wide growth for single and multiwire applications of preparing the wire surface for cold forming.

Even though the product quality and environmental aspects were from the beginning on superior to traditional techniques, the throughput of the process was not comparable with coil processing systems. Our newly developed method of wire contacting inside the coating chamber, has enabled us to virtually double the line speed, thus double the approximate annual capacity.

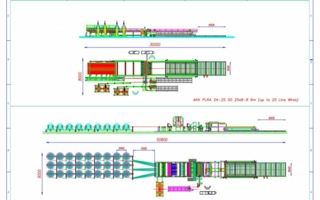

This is what Staku is offering today as most modern concept, state of the art manufacturing in the 21st century:

– Environmentally friendly processes which avoid the use of acids

– Space savings with equipment which requires the smallest footprint, and foundation work for secondary containment is not required

– High quality “inline production system” at high speeds and qualities with “e systems”

– Homogeneous coating quality around the surface, no voids resulting from contact spots

– Fully automated chemical analyzation and metering system connected to Level 2/3 Process Data Network

– Lowest processing costs due to:

1. Low energy costs, all bath temperatures between 50°C – 60°C, fully enclosed closed-loop system provides for optimal heat retention.

2. No formation of waste sludges and rinse water at disposal

3. No down time for bath cleaning due to permanent in-line filtration

4. Significant reduction of chemicals due to electrochemical reaction

5. No harsh chemical odor or equipment contamination in the surrounding area

Features of the Staku “e phos” and “e molyphos” Production Concept:

1. Descaling

Generally, we are recommending two different methods of descaling with one chosen based on the wire diameter range produced on the machine.

– Diameter range from 5.5mm to 16mm: double sand belt cleaning machine

– Diameter range from 17mm – 38mm: 4 turbine shot blaster machine

2. Phosphating

The electro phosphating process is driven by a directed power source DC which is creating an electrical potential higher than the natural one existing between the elements iron and zinc. The System voltage is very low, it will never exceed 8V – 13V making it safe for the operators.

In comparison to the traditional phosphating, the phosphate crystals are not growing in a natural way as they do in a thin, needle-shaped form. shape.

Caused by the use of DC power, the zinc-phosphate crystals will be electrically deposited by ion migration from the anode to the wire surface which will be polarized as the cathode. For optimization of the coating quality around the wire surface, the electrodes are built in a round shape.

Beside the fine crystalline phosphate structure, the DC power is suppressing the pickling process which is necessary for the traditional phosphating. Because the iron ions from the wire cannot contaminate the phosphate solution, the formation of phosphate sludge cannot happen and directly saving a significant amount of chemicals and reduce waste cost.

3. Line speeds and capacities of inline phosphating

rod diameter (mm) |

coil weight (t) |

Coil length (m) |

desired speed (m/s) |

processing time (min) |

eff. capacity (t/h) |

7.5 |

2.0 |

5,760 |

2.0 |

48 |

5.0 |

13.0 |

2.0 |

1,920 |

2.0 |

16 |

7.5 |

20.0 |

2.0 |

820 |

1.5 |

9 |

13.3 |

wire 2022, hall 9 booth C 80

Staku-Anlagenbau GmbH

Bahnhofstraße 33-35, 35423 Lich, Germany

Contact person is Elisabeth Proksch

Tel.: +49 6404 2031

elisabeth.proksch@staku-gmbh.de

www.staku-gmbh.de