01/04/2022 – NDC Technologies introduces new products

Value of intelligent, connected measurement and control

NDC Technologies, global provider of connected, measurement and process control solutions, will be introducing several new products at “wire”.

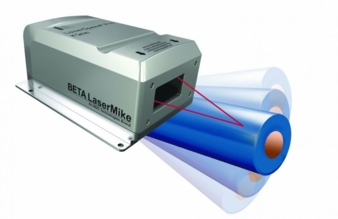

Visitors stopping by NDC Technologies (Beta Laser Mike Products) will see firsthand how precise, reliable measurements along the critical points in the cable extrusion process can help manufacturers significantly improve product quality, increase productivity and realize significant production savings.

NDC Technologies first introduced “Lay Scan”, the industry’s only and most innovative solution for accurately and consistently measuring the lay length of twisted pairs at the cabler. NDC is debuting its new innovation – “Lay Scan Pro” – which takes lay length measurement one step further. This one-of-a-kind solution enables cable makers to precisely monitor and control the lay length of twisted-pair cables are they are being made inside the bow of a twinning machine.

NDC will be debuting its new “Accu Scan Pro” single-axis diameter gauge with applications versatility that provides 100% inspection of multi-strand wire during production. “Accu Scan Pro” accurately measures the diameter of multi-strand wire and detects missing and broken strands, simultaneously. The system monitors processes in real time for a complete view of product quality.

Unlike anything on the marketplace today, NDC’s new “Laser Speed Pro M” Series gauge accurately and reliably measures the length and speed of long, continuous cylindrical products during production that bounce and cannot be well-guided, move off-axis or are out of the measurement range.

NDC Technologies Inc.

wire 2022, hall 11 booth D 68

Tel.: +1 937 233 9935

Other products on display at the NDC Technologies (BETA LaserMike Products) booth include:

– “Center Scan 2010”: non-contact insulation diameter and conductor eccentricity measurements

– “LN 3000” series: high-accuracy, three-axis lump and neckdown detection

– “Laser Speed Pro”: non-contact length and speed with the highest laser precision

– “Cap Scan”: drift-free, in-process capacitance measurements

– “EFL Pro”: excess fiber length measurements

– “SRL Pro”: on-line structural return loss prediction

– “Bench Mike Pro”: the industry's leading off-line diameter and ovality sample part inspection system

– “In Control / Data Pro”: advanced process visualization and control

For more information, visit www.ndc.com/betalasermike