19/05/2022 – Spring manufacturing

Present and future of quality spring production

After an interruption of four years, Simplex Rapid – trendsetter in the wire industry for over 70 years – is coming back to “wire”. During these challenging times, the company – located in Milan – renewed their efforts towards OPC-UA cross-platform data exchange and M2M technologies, energy efficiency, increase of output rates and accurate selection of the produced springs.

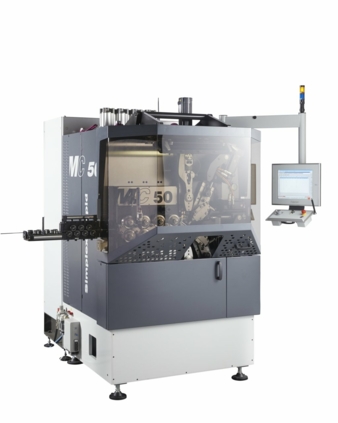

In their booth, it will be possible to see the coiling machines “MX” and “FX”, with wire diameter range from 0.1mm to 3.00 mm, and the coiler “MC50” for wire range up to Ø 5mm (the MC machines can coil wire with maximum diameter of 14mm).

It will also be possible to virtually see a preview of the new family of coiling machines for fine wire with a range going from Ø 0.05mm to 0.2mm (for medical and microelectronic purposes).

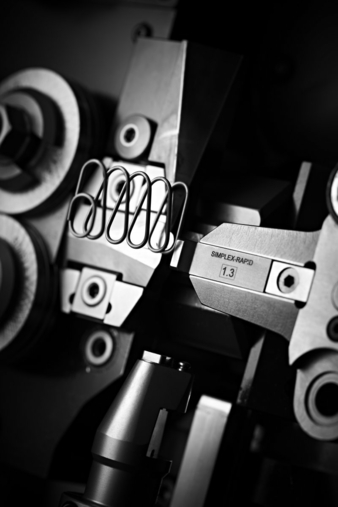

All machines are equipped with the International Patent “Coiling Finger Rotation” device, which thanks to its 1-2 independent axes can check and modify the spring pre-load during each phase of the production cycle.

Such patent allows to eliminate completely the problem of the first coil deformation, thus succeeding in obtaining a spring with the desired overall preload and perfectly symmetrical ends.

Simplex Rapid manufacture machines with extreme precision, and they implement unique ergonomic solutions to ensure that even the few micrometric adjustments not controlled by the brushless motors are easily repeatable.

All the machines will be network-connected; production and diagnostics data will be collected and displayed on specific screens (Industry 4.0).

All coiling machines will be connected with P Series Pay-offs (weight capacity from 50kg to 2,000kg). Thanks to the advanced auto-adaptative software, the rotation of the wire holding plate can be optimized by keeping unvaried the tension of the wire entering the working machine, regardless of machine parameters.

Refined mechanical solutions, ceramic pulleys, and lower weight on components touching the wire make our pay-offs the perfect choice for high speed production with fine wires.

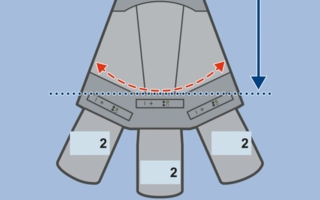

Simplex Rapid will demonstrate how their vision measurement systems work (diameter and length of the springs), as well as our innovative sorting chutes.

The increasing production speed and the necessity to narrow down the tolerance make these devices a must-have to achieve a zero-scrap production.

The last generation type C sorting chute, a revolutionary patented device developed for sorting at high speed (>1500 cycles/min), guarantees the verification of the correct sorting operation thanks to sensors, which stop the production process when they detect any discrepancies in the spring sorting process (both non-compliant and scrap springs).

wire 2022, hall 13 booth C 15

Simplex-Rapid s.r.l.

Via Lombardia, 13, 20098 S. Giuliano Milanese, Italy

Contact person is Vittoria Boschiero

Tel.: +39 02 98281751

v.boschiero@simplexrapid.it

www.simplexrapid.it