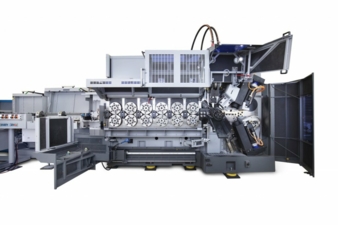

01/06/2022 – Cold forming production with the Spring Coiling Machine “FUL 226”

Pushing the limits

The “FUL” series of spring coiling machines from Wafios meets the highest standards. In combination with a high degree of user-friendliness, the machines are designed with maximum productivity and quality in mind.

The models that end in a “6”, which include the new “FUL 226”, always represent the latest stage of development and feature cutting-edge mechanical systems and control technology. The modular design offers the most flexible application possibilities and impresses with a wide range of options, like the “PTP” coiling finger for initial tension control during the production of springs.

Numerous new developments enable the Wafios “FUL 226” to reliably produce suspension springs from high-strength, oil-hardened and tempered wire up to 22mm diameter and a tensile strength of 2,000MPA or from mild steel wire of up to 30mm and a tensile strength of 800MPA employing the 2-finger coiling technique. The “FUL 226” is a real powerhouse – it has to be, with wire thicknesses of up to 22mm. The infeed force can be increased to such an extent that for short periods of time even the smallest of spring indexes (wm<3,5) can be realized. Whenever extreme forces are involved, stability and robustness is an absolute must. The entire modular machine assembly complete with infeed and coiling body is therefore connected to the base. The “FUL 226” is the first Wafios spring coiling machine that has a wire feed unit with 6 pairs of feed rollers and two more pairs of feed rollers as an option. When using mild steel wire up to 30mm, a seventh and eighth pair of feed rollers can be added. This allows a reduction of the contact pressure per pair of rollers and thus a gentler feeding in of the wire.

Nevertheless, the “FUL 226” features all the familiar advantages of the “FUL” series: e.g the Wafios programming system “WPS 3.2” and of course numerous “iQ” functions for optimizing processes, like “iQautopitch” for the automatic correction of the diameter and pitch while setting up a spring, or “iQcontrol” for in-process spring length measurement. “iQspring2FUL” for automatically generating a spring program after scanning in a reference spring, is a new feature that has been added.

Keeping downtimes to a minimum is a design principle that runs through the entire machine. The basic idea is clear: minimize changeover time to maximize machine availability. This is achieved by an easy change of tools using a mounting aid, a dual-coil pay-off system, a semi-automatic wire insertion device, a two-step, in-process clamping of the mandrel and a high accessibility of the machine without neglecting operator protection.

The standard equipment of the “FUL 226” includes 8 CNC axes that cover the basic functions but also other options: infeed, straight cut, parallel pitch, mandrel slide adjustment and coiling. More axes can be added, e.g. a 4-axes coiling device or the “PTP” coiling finger for right- and left-hand coiled springs in order to vary the pitch and initial tension of the spring during the coiling process.

The machine also meets high standards when it comes to quality control. This task is entrusted to the “Wafios Vision System” (WVS). The springs produced are measured in terms of length and diameter using a camera and backlight and are then accordingly adjusted during production operation. Using new artificial intelligence techniques, the coiling results of multiple springs produced are evaluated and applied to the production process which results in even higher spring quality.

The machine is controlled via the reliable programming system Wafios “WPS 3.2 EasyWay”. It supports the operator in setting up and operating the machine and increases the availability of the “FUL 226”. The hardware meets the high Wafios standards and includes a 24" multi-touch screen with gesture-based control as well as a hand-held operating device for set-up operation that is also equipped with a touchscreen. “VPN” and “OPC-UA” interfaces enable secure access to the machine e.g. for remote maintenance services or the integration of the “FUL 226” into existing digital production structures.

Increased productivity and process reliability

The engineers paid special attention to the handling of metal wire coils in order to both minimize downtimes and eliminate safety risks. The diameter range of the pay-off unit “AHS 8” has been increased to 22mm for spring steel wire and to 30mm for mild steel wire. The drive of the pay-off unit is synchronized with the drive of the spring coiling machine. The pay-off unit is equipped with a motor-driven adjustment of the centering stanchions and an automatic detection of the centering position. As an option, the “AHS 8” can be equipped with a tilting function to facilitate and accelerate the loading of the wire coil. The vertically adjustable wire insertion device facilitates the processing of mild steel wire up to 30mm.

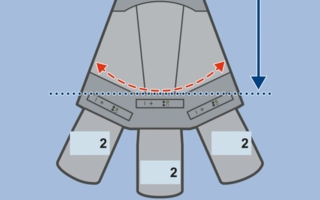

The new, patent-pending technique with auxiliary feed unit and wire insertion device, for the semi-automatic handling of the wire, minimizes safety risks and ensures a reliable transport of the wire from the pay-off unit to the auxiliary feed unit of the spring coiling machine. Special features are a vertically adjustable, motor-driven clamping unit for securing the wire beginning, a gear motor, a carriage with rollers and cable carrier as well as a separate hand-held operating device. As an option, the pay-off unit is available as a dual-coil pay-off unit with displacement device to further increase the machine's productivity, to decrease the machine's downtimes and to be able to change to a different wire diameter more quickly, also see fig. 2 “FUL 226” with dual-coil pay-off unit.

New dimensions in cold-forming suspension springs

The cold-forming production of springs made of high-strength wire has several advantages over the hot-forming production process. In the past, accordingly dimensioned suspension springs have usually been wound in a hot-forming process that required a lot of energy. Further disadvantages of the hot-forming process are the considerable amount of dirt arising, the limited product variety caused by geometrical limitations, the hardening process and high safety requirements due to legal regulations. The cold-forming process, however, offers new possibilities for the industry, especially in terms of the springs' – also double-conical springs' – freedom of geometry. Due to the possibility to produce right- and left-hand coiled springs and due to the in-process adjustments made possible by the “PTP” coiling finger, the machine is perfect for the production of technical springs or suspension springs that require initial tension or closed/inside positioned spring ends. It meets the requirements of new markets created by the restructuring of the automotive industry.

Due to the dimensions of the “FUL 226”, it will be presented digitally at the wire show. Its little sister, the “FUL 126” can be seen live, see overview of Wafios “FUL” series (fig. 3). “Forming Future Technology”, visit Wafios at the wire/Tube 2022 – Hall 10, booth F 22 / F 40, register now at https://wireandtube.wafios.com

wire 2022, hall 10 booth F 22/40

Wafios AG

Silberburgstrasse 5

72764 Reutlingen, Germany

Tel.: +49 7121 146-0

sales@wafios.de

www.wafios.com