The compact SXF hoists provide efficient and reliable lifting for horizontal and vertical transport across a wide range of industrial applications. © Columbus McKinnon

The compact SXF hoists provide efficient and reliable lifting for horizontal and vertical transport across a wide range of industrial applications. © Columbus McKinnon

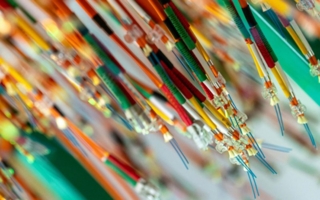

Europa hält derzeit nur noch einen Anteil von etwa 15 % an der weltweiten Produktion von Glasfaserkabeln. © LWL-Sachsenkabel

Die Welt des Verpackens ändert sich gerade rasant. Wie, das zeigt die Fachpack-Messe in Nürnberg. Auf dem Bild ist eine Schwerregal-Lagerlösung für Metallbleche zu sehen, die je Regalboden 2,5 t Gewicht tragen kann. Sie stammt von Aalbers Farina. © Meisenbach

Gebäudefassade oberhalb des Eingangs zur Rettungsdirektion Secours Sarine in Fribourg. © Schäfer Werke