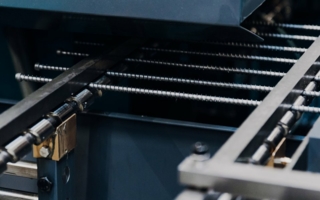

19/09/2023 – 80 full-thread screws of up to 420mm length produced on a single machine in one minute

80 full-thread screws of up to 420mm length produced on a single machine in one minute

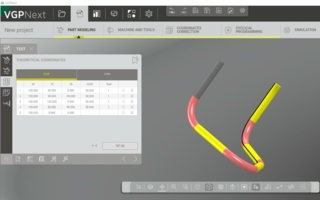

Aachener Maschinenbau GmbH (Amba) has further enhanced its proven All-in-One machines for long-screw production: The machines are now able to produce up ...