14/03/2023 – Two series of feeding units

Gentle process material transport

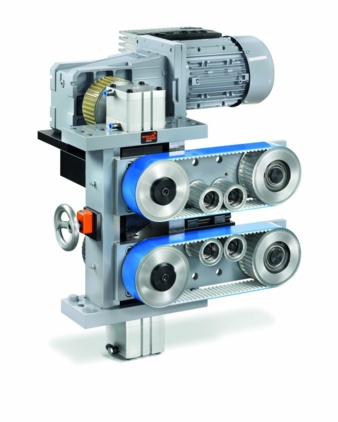

For the processing of flat wires, narrow strips, profiled wires and tubes, feeding units with transport belts are increasingly being used to provide the transport force required for peripheral processes.

As an alternative to transport rollers, they offer a greater coefficient of friction and lower pressure in contact with the process material. This ensures gentle process material transport and, for given values for pressure force and torque, greater transport forces are achieved with transport belts than with transport rollers.

“NAK” and “NAK Z” series

Witels-Albert offers two series of feeding units with transport belts. The models of the “NAK” series differ from those of the “NAK Z” series in the way of clamping the process material and in the performance. All “NAK” models clamp a process material with a fixed edge. The “NAK 60 Z” and “NAK 160 Z” feeding units, on the other hand, use transport belts as tools that clamp the process material centrically. Each transport belt of a feeding unit of the “NAK Z” series is arranged on a movable chock which can be adjusted in the direction of the material by means of a pneumatic cylinder in order to clamp it. The adjustment of the chocks is set manually in the open state by a wedge which, by means of a spindle mechanism and an associated mechanical position indicator, permits the reproducible setting of the transport gap. This is particularly advantageous for handling process materials that are highly susceptible to deformation.

Defined centric clamping

When the transport gap is set, the magnitude of the normal force follows from the reaction force, which is formed from the elastic spring-back forces of the process material cross-section and the back coating of the transport belt. The principle enables defined centric clamping of process material diameters or symmetrical cross-sections with thickness dimensions between 0.6mm and 15.0mm (“NAK 60 Z”) or between 0.6mm and 40.0mm (“NAK 160 Z”).

A process material is transported when torque is applied to the shafts of a feeding unit which, together with the respective associated toothed pulleys and axles including a toothed pulley with bearing, form two traction gears. They are supplied with torque via a rear-applied actuator (motor/gearbox) with drive toothed pulley, a drive toothed belt with teeth on both sides and two further drive toothed pulleys of the shafts. The tension of the drive toothed belt can be adjusted by the rear-mounted pneumatic cylinder, which positions a toothed pulley translationally.

Different back coatings

Depending on the model of a feeding unit and the specific transport task, transport belts are offered with different back coatings. The material of a back coating determines the elastic spring-back force, the feed precision and the wear resistance. An important characteristic value is the hardness (Shore A, Shore D), which is indirectly proportional to the coefficient of friction, which influences the transport force proportionally.

The tribological system is complex and must be designed to suit specific applications. For example, polar polymer materials as back coatings promote static friction through the formation of adhesion forces and adhesive bridges to smooth metallic surfaces. The greater coefficient of friction results in a greater transport force, but favors abrasion or wear.

“NAK Z” series feeding units are characterized by perfectly coordinated subsystems, each of which stands for high power density and ensures low-slip process material transport. Achievable transport forces of the feeding units with transport belts in sizes of 0.5kN (“NAK 60 Z“) and 2.5kN (“NAK 160 Z”) lead to a dominance in competition with feeding units of equivalent size that use transport rollers as tools.

All models are supplied ex works without or with actuator. The “NAK 60 Z” and “NAK 160 Z” feeding units have holes for mounting in horizontal and vertical installation positions. As partly completed machinery in accordance with Directive 2006/42/EC, the feeding units are supplied without guards and without controls. A declaration of incorporation and assembly instructions are binding parts of the contract when a partly completed machine “NAK” or “NAK Z” feeding unit is purchased.

Witels-Albert GmbH

Malteserstrasse 151-159, 12277 Berlin, Germany

Contact person is Marcus Paech

Tel.: +49 30 72398811

paech@witels-albert.com

www.witels-albert.com