20/03/2023 – Wire drawing / Simulation

Wire drawing with “Copra”

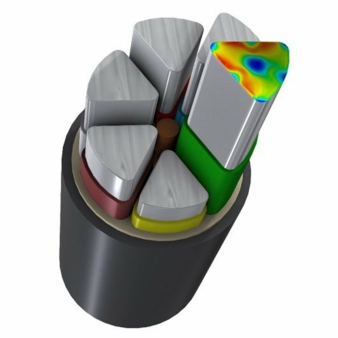

The new version of “Copra FEA RF Wire Rolling” now also includes a feature to simulate shaped wire drawing. The software considers the nonlinear plastic and elastic material properties, friction and relaxation between the drawing dies and delivers results within a few minutes. Annealing steps can also be included if wanted.

Wire drawing is a metalworking process that is known and successfully used for thousands of years. It is used to modify the cross-section of a wire by pulling it through a single, or a series of drawing dies. Wire drawn products can be either round or shaped and can be found in a variety of applications, such as electrical wiring, cables, tension-loaded structural components, springs, paper clips.

Especially when it comes to shaped wires and advanced materials, the engineering of the process and the design of the dies can be a challenging task. Experienced designers and lots of trial runs are necessary to reach a satisfying process and product quality. These approaches are neither sustainable nor cost-effective. Therefore, a lot of interesting inquiries with difficult profile geometries get rejected in fear of taking a business risk.

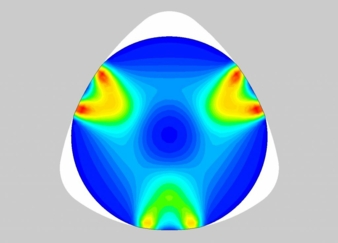

To support the engineering work and reduce the amount of trial runs, process simulation should be used. In order to detect possible design errors at an early stage and avoid costly commissioning, a continuous process chain from design to the virtual trial run is the way to go. The use of numerical methods to simulate the wire drawing process by means of non-linear, elasto-plastic finite element analysis (FEA) not only improves the speed and quality of tool design, but also leads to a better understanding of the wire drawing process.

With the “Copra RF Wire Rolling” solution by data M, the entire design process can be mapped.

As known from other “Copra” products, the software user does not have to be a simulation specialist. The complex simulation models can be created with a few mouse clicks and the simulation results are available in minutes. Investigating the results is easy, as the user is supported by many automatic functions, that deliver the essential information for the optimization of the process design like e.g. wire cross section geometry, drawing forces or work hardening. Thanks to the integrated “Marc” further analyses of the part are also possible.

This new feature enlarges the portfolio of manufacturing processes that can be simulated using software from the “Copra” product family.

Data M Sheet Metal Solutions GmbH

Am Marschallfeld 17, 83626 Valley/Oberlaindern, Germany

Tel.: +49 8024 640 0

datam@datam.de

www.datam.de/en/