08/11/2023 – Predicting microstructure evolution during wire manufacturing

Simulation-based microstructure prediction

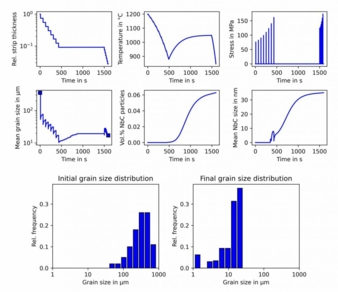

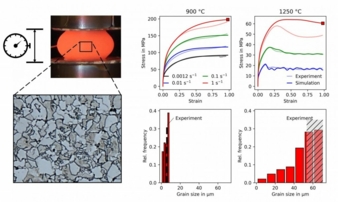

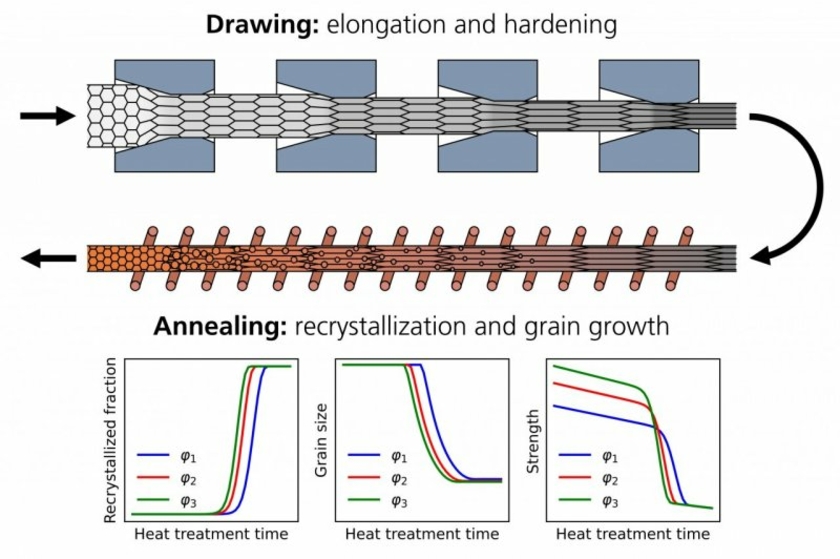

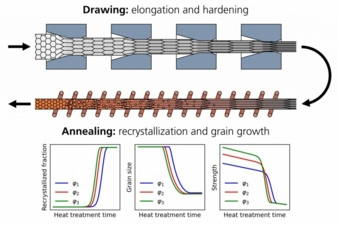

The simulation of material behaviour is an important tool in process design. A model developed at Fraunhofer IWM allows predicting microstructure evolution during wire manufacturing. A simulation program makes the model available for practical application.

Fig. 1: The Fraunhofer IWM material model predicts the microstructure evolution during wire manufacturing. The computational variation of the process conditions allows to predict their effects on the product properties. © Fraunhofer IWM

Fig. 1: The Fraunhofer IWM material model predicts the microstructure evolution during wire manufacturing. The computational variation of the process conditions allows to predict their effects on the product properties. © Fraunhofer IWM