The new heat transfer test facility from Primetals Technologies allows for optimization of industrial cooling systems. © Primetals

The new heat transfer test facility from Primetals Technologies allows for optimization of industrial cooling systems. © Primetals

Electric motor production: The aim of the “MotorInspector” research project is to improve quality control. (Photo: industrieblick, https://stock.adobe.com/) © IPH Hannover

Groundbreaking interconnection technology using 200 nm nanowires to realize tomorrow’s high-performance electronics. (close-up) © Fraunhofer IZM

Lubricants based on polymers make the process of wire drawing significantly more environmentally friendly and economical. Kristin Stein © Fraunhofer IAP © Fraunhofer IAP

“µDRAL” plant – first direct reduction plant flexibly operated with hydrogen and natural gas in an integrated mill. © Salzgitter

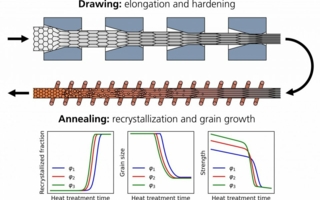

Fig. 1: The Fraunhofer IWM material model predicts the microstructure evolution during wire manufacturing. The computational variation of the process conditions allows to predict their effects on the product properties. © Fraunhofer IWM