08/11/2023 – Predicting microstructure evolution during wire manufacturing

Simulation-based microstructure prediction

The simulation of material behaviour is an important tool in process design. A model developed at Fraunhofer IWM allows predicting microstructure evolution during wire manufacturing. A simulation program makes the model available for practical application.

Various reasons require the continuous development of wire manufacturing processes and materials: high quality standards require minimizing faults and process deviations; efficiency improvement is crucial due to rising energy costs; moreover, to maintain competitiveness, all potentials for productivity increase should be exploited. At the same time, there is a need to reduce costs for process and product development raising the question of how to make development cycles as targeted and fast as possible. Simulation methods are a key resource for coping with this challenge, as they notably reduce the number of necessary pre-production tests. By systematically investigating potential scenarios, promising process variants can be narrowed down on the computer. This makes it possible that the first prototype is already close to the final product.

Simulation of the entire process chain

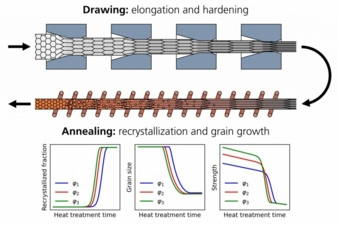

At the 15th Branchentag Draht (German wire industry day) in Iserlohn, Germany, on September 29, 2023, the Fraunhofer Institute for Mechanics of Materials IWM presented a model for the simulation of material behaviour. The model has been developed to support in analyzing, designing, and optimizing forming and heat treatment processes by predicting changes in the thermo-mechanical material properties and microstructure as a function of the process history (see also references [1] and [2]). Variables such as yield stress and grain size, as well as the recrystallized fraction of the microstructure, can be analyzed throughout all process stages (Fig. 1). Moreover, for materials capable of forming precipitates, the particle volume fraction and size are predicted, along with the influence of precipitates on recrystallization and strength.

This approach makes it possible to simulate the entire process chain without transferring data from one model to another between individual process steps (Fig. 2). For example, material behaviour during wire rolling, drawing, and annealing can be continuously predicted. Studying the influence of each process step provides insight into the correlations between process parameters and material behaviour. By selectively varying specific process parameters, it becomes possible to predict how to enhance the entire process chain to reduce time, energy, and cost while attaining the intended product characteristics.

A novel software solution

The material model is implemented as a stand-alone simulation program, making it available for industrial use in a user-friendly manner. The simulation model has already been used for various industrial applications. Specifically, it has been applied to hot forming for both steel and nickel-based alloys. In addition, it is currently being validated for simulating the heat treatment of drawn copper wire. In various research projects, both the material model and the accompanying simulation software are continuously improved and extended.

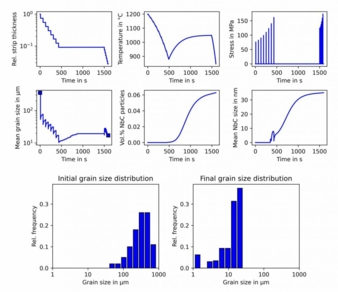

The material model developed at Fraunhofer IWM is based on physical principles and allows a realistic representation of complex material behaviour. As a consequence, its calibration for a specific material is a manageable task. Typically, forming and/or heat treatment experiments are performed under controlled conditions on a laboratory scale. To investigate the impact of process parameters of changes in microstructure, the specimens are analyzed by metallography prior to and after the experiments. The model parameters are adjusted in such a way to ensure that the simulation model accurately reproduces the process-dependent material properties and microstructure evolution observed in laboratory experiments (Fig. 3). As a leading academic partner for industry, Fraunhofer IWM offers a complete range of services, including thermo-mechanical testing and metallography, as well as the model parameter identification.

Literature

[1] Kertsch, L.: Modellierung des thermomechanischen Materialverhaltens und der Gefügeentwicklung mikrolegierter Stähle (Modelling thermo-mechanical behaviour and microstructure evolution of microalloyed steels), Dissertation, Karlsruher Institut für Technologie, Karlsruhe, Germany, 2022, https://doi.org/10.24406/publica-222.

[2] Kertsch, L.; Helm, D.: A thermodynamically consistent model for elastoplasticity, recovery, recrystallization and grain coarsening, International Journal of Solids and Structures 152–153, 185–195, 2018, https://doi.org/10.1016/j.ijsolstr.2018.06.026.

Fraunhofer-Institute for Mechanics of Materials IWM

Wöhlerstrasse 11, 79108 Freiburg/Germany

Contact person is Lukas Kertsch

Tel.: +49 761 5142-479

lukas.kertsch@iwm.fraunhofer.de

www.iwm.fraunhofer.de