21/05/2022 – Surface treatment

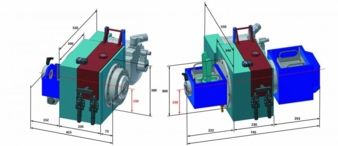

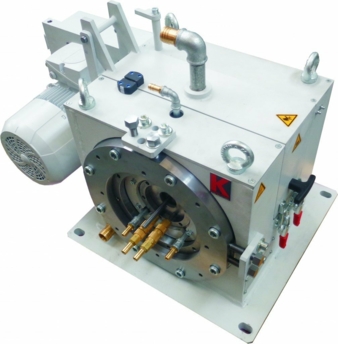

Wire shaving unit for non-ferrous wire processing 2.0

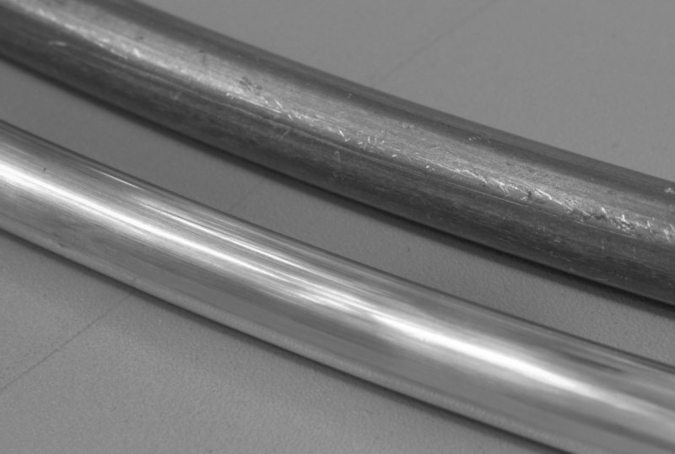

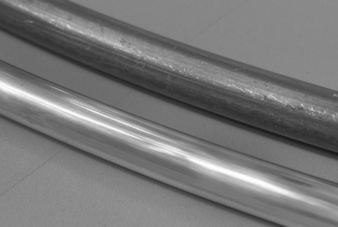

For several years the number of applications of wire shaving technology even in the non-ferrous range, especially for the processing of copper and copper alloys as well as aluminium and aluminium alloys has increased. Kieselstein consequently implements the experience of the recent years into a new design of its shaving units.