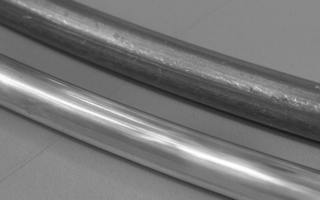

Suzuki Garphyttan is now investing heavily in development and making significant investments in all production facilities in order to be able to offer high-quality products in more product areas, for example in forming and annealing. © Suzuki Garphyttan