24/09/2020 – Weaving technology

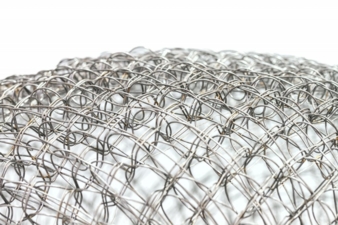

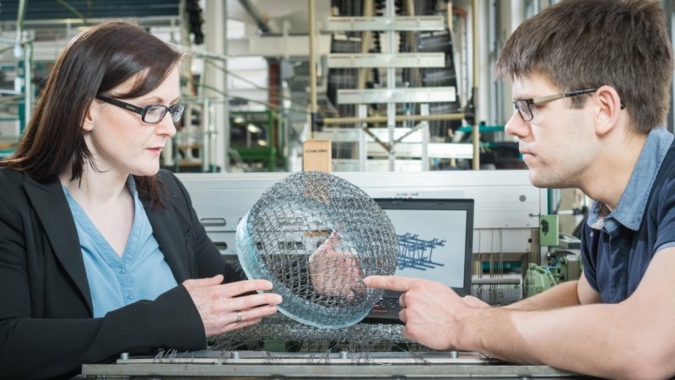

Woven cellular metals made of wires

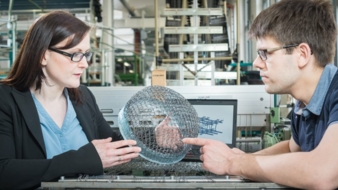

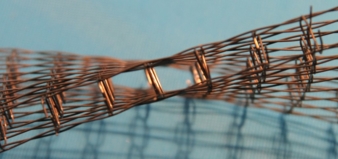

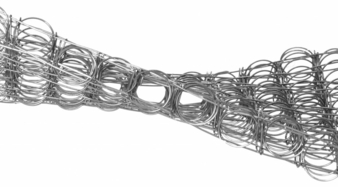

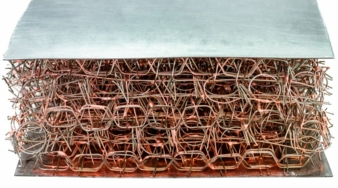

A team of researchers at the TU Dresden has succeeded in producing three-dimensional cellular metals from wires with the help of weaving technology. The patented structure enables the production of metallic lightweight materials with a wide range of properties and offers new possibilities for lightweight metal construction.

Fig. 1: Cellular metals from wire developed at the ITM of TU Dresden. © ITM, TU Dresden, Mirko Krziwon