22/05/2025 – Niehoff technology: Flat wire drawing and annealing

Producing flat copper wire for cable shieldings

The copper shielding around the insulation layer is an important component of HV and EHV cables. It acts as a protection shield against electromagnetic radiation and is usually made of round wires. Flat wires, however, would be much more advantageous for several reasons.

The cross-section of flat wires can be used more effectively than the cross-section of round wires, the cavities for the wires would be smaller if flat wires were used, the number of wires – and therefore the amount of material required – would be reduced and the gaps between the individual wires would be narrower, which in turn would increase the shielding effect. These advantages, however, were countered by the widespread opinion that flat wires had to be produced by flat rolling, a process which is considerably more time-consuming and therefore more expensive than drawing round wires.

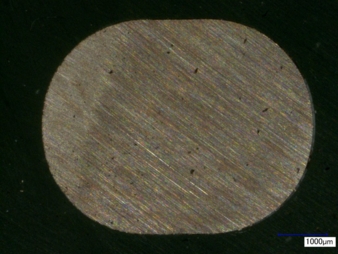

This limitation is now eliminated by a process developed by Maschinenfabrik Niehoff together with a well-known cable manufacturer. In this process, wire rod is drawn into flat wire and annealed in a single operation. The manufacturing process can be carried out on any existing Niehoff rod breakdown (RBD) machine with appropriate modification; additionally, a spooler equipped with a specially developed flat wire laying device is required. In the present case, wire rod with a diameter of 8mm is drawn and annealed on an existing “MSM 88 + R 503” type “RBD” line in eleven drafts, nine of which are through shaped dies, into flat wire with a cross-section of 4.852 m x 0.677mm (= 3.192mm²) at a production speed of 20m/s. This flat wire fulfils all the requirements placed on it (figs. 1 to 4).

The process, which has already proven itself in practice, works faster than rolling processes and makes it possible to produce high-quality flat copper wire for cable shielding reliably and economically.

Complete solutions from a single source

With more than 70 years of experience in the wire and cable industry, Maschinenfabrik Niehoff builds machinery for the production of non-ferrous wires and their processing into automotive, power, data and special cables.

Niehoff pays great attention to the longevity of its products and is committed to manufacturing machinery that is characterized by reliability, process stability, high productivity, energy and materials efficiency, and reduced CO2 emissions. Niehoff is certified by the German Environmental Auditors Board EMAS, belongs to the Blue Competence sustainability initiative of the German Engineering Federation (VDMA) and with regard to its corporate social responsibility (CSR) cooperates with the international platform for sustainability ratings EcoVadis.

Niehoff Group has a workforce of around 1300 employees worldwide and is comprised of its headquarters, its branch plants at Leuterschach (Germany) and NST in Badalona-Barcelona (Spain), manufacturing subsidiaries in Brazil, the US, the Czech Republic, India, China, and Sweden along with sales and service centers in Japan, Singapore, and Mexico.

Maschinenfabrik Niehoff GmbH+Co. KG

Walter-Niehoff-Strasse 2, 91126 Schwabach, Germany

Tel.: +49 9122 977-0

info@niehoff.de