04/05/2020

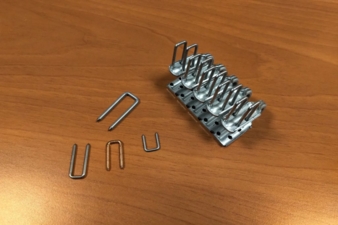

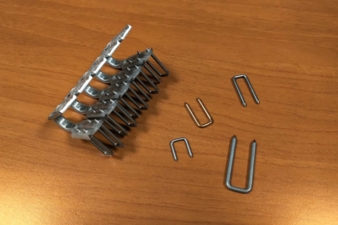

Special machine to produce U-staples

Baudrand New Tech is proud to introduce its ability to respond to special parts manufacturers needs with special equipment. Acting in the field of wire and strip forming since 1992, Mr Jean-Marc Baudrand, the founder and owner explains that the french company has been approached, a year-ago, by a producer of special technical staples used in the conveyor-belt industry.

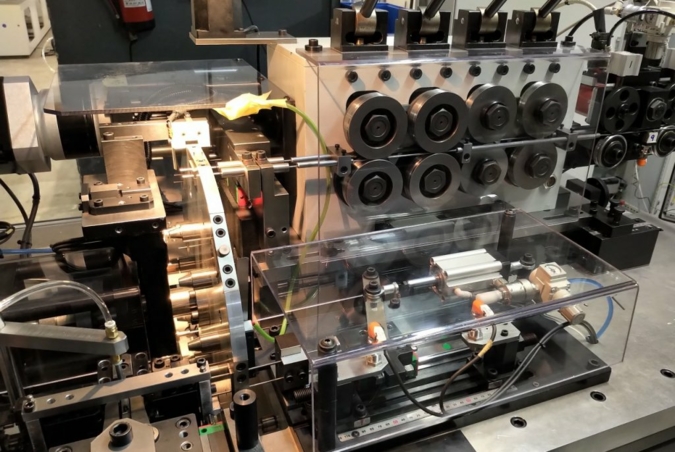

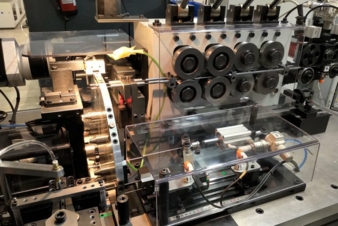

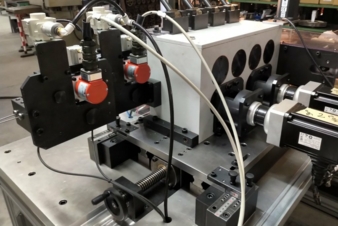

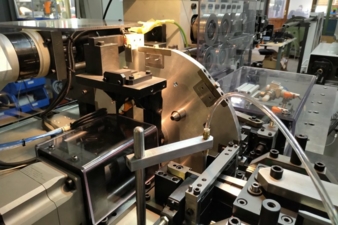

Wires go through a double rotary straightener, which mechanical set-up is brought by means of a motorized and digital system. © Baudrand

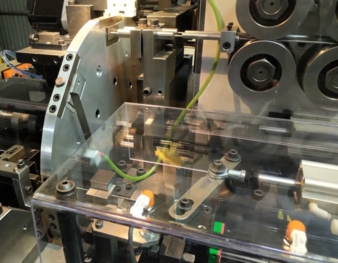

Each wire feeding is provided by a dual set of 4 feed rollers, with quick clamping and opening. © Baudrand

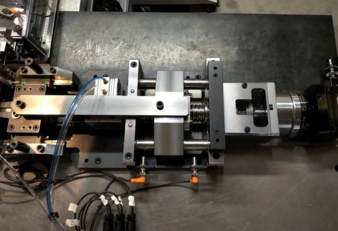

Cut-to-length wires are brought and hold in a indexing plate, rotating around an horizontal axis. © Baudrand