25/05/2022 – The global footprint means the world to Suzuki Garphyttan

Significant investments in all production facilities

It all started in 1906, in the small village Garphyttan in the heart of Sweden. Today, Suzuki Garphyttan is a global and well-known player with more than 600 dedicated employees, creating innovative steel wire products for high-performance applications in a wide range of industries.

The goal is to be a complete supplier of wire made from carbon steel, low alloy steel, stainless steel and other high-alloy materials. © Suzuki Garphyttan

Suzuki Garphyttan is now investing heavily in development and making significant investments in all production facilities in order to be able to offer high-quality products in more product areas, for example in forming and annealing. © Suzuki Garphyttan

One example is the shaped wire with cross-sections that can be rectangular, flat, or trapezoid. © Suzuki Garphyttan

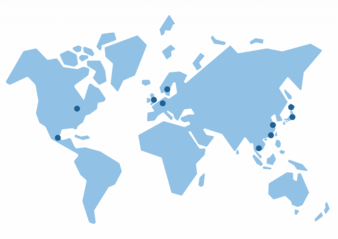

“Local production is important for us to continue to offer our customers high quality, flexibility and service levels,” states Ola Ericsson.Ola Ericsson business area manager APAC. © Suzuki Garphyttan

“This means that we can maintain high quality, while at the same time ensuring a stable supply of wire to customers in each region.” © Suzuki Garphyttan

The goal is to be a complete supplier of wire made from carbon steel, low alloy steel, stainless steel and other high-alloy materials. © Suzuki Garphyttan

Ola Ericsson, Program Manager Non-Automotive and Business Area Manager APAC, says: “We can quickly and smoothly meet local needs, thanks to our own production facilities in Sweden, the US, Mexico, China and England and through our owner Nippon Steel with facilities in Japan, China and Thailand. © Suzuki Garphyttan