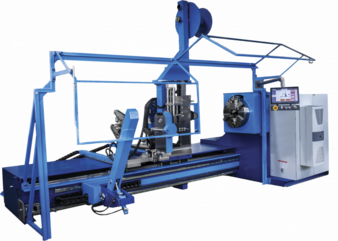

22/05/2022 – The “WIM CNC” for cold or hot coiling

Fully automatic lathe coiling machinery

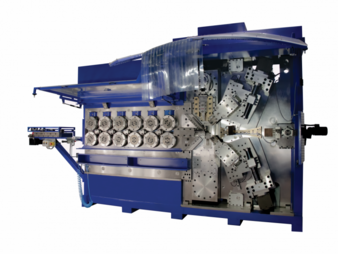

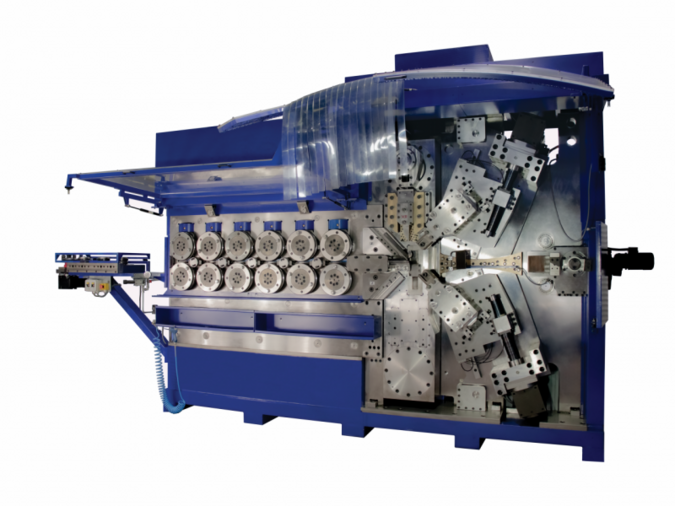

Fortuna Federn will present at “wire” its latest products from all their machinery lines including latest spring coilers “COM” and “WIM CNC”, spring end grinders “GRM CNC”, wire bending tables “BEM CNC”, double torsion production machinery “LDT CNC”, spring loopers and many more.

With “COM CNC” line Fortuna has reached potential of delivering custom made solution for large mass production. © Fortuna Federn