18/09/2025 – Ideal for wires from 1mm to 100mm in diameter

Efficient flash butt welding

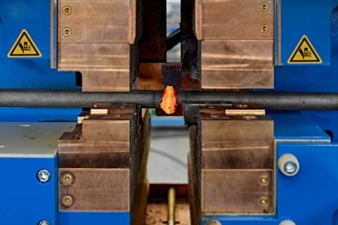

The flash butt welding process is a proven technique in industry, enabling fast, high-quality, and standards-compliant connections.

The process consists of three main steps: preheating, burning, and forging.

Especially suitable for large diameters

This method is highly versatile and particularly well-suited for wires with diameters ranging from 1mm to 100 mm. This makes it an ideal solution for heavy industries and applications involving extremely thick wires.

Key Benefits

– High-strength, reliable joints

– Rapid welding times

– Oxidation protection without additional gases

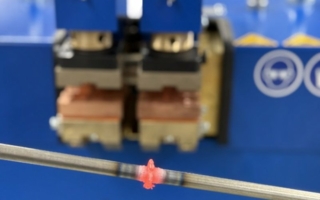

– Easy in-machine deburring

– Broad applicability across various wire sizes

Conclusion

The flash butt welding process impresses with its flexibility and quality — even at very large diameters. Its integrated deburring step ensures clean and smooth wire end-product, making it a dependable ideal solution for demanding industrial applications. The industrial solution, the type “AS0 100 S-K” flash butt welding and deburring machine.

Cable & Wire West Coast Pavilion 2025, booths 423 and 623

at Manufacturing Technology Series West

Ideal-Werk C.+E. Jungeblodt GmbH+Co. KG

Bunsenstrasse 1

59557 Lippstadt/Germany

Contact person is Michael Tieze

Tel.: +49 2941 206-111

tieze@ideal-werk.com

www.ideal-werk.com

Other upcoming fairs

Cable & Wire Fair 2025, hall 3 booth Q2-1, in New Delhi/India