Ideal-Werk

18.09.25 – Ideal for wires from 1mm to 100mm in diameter

Ideal for wires from 1mm to 100mm in diameter

Specifically engineered for the demanding chamber welding process, these machines are perfect for efficiently joining strands and conductor cables. © Ideal-Werk

07.11.24 – Joining / Welding

Joining / Welding

A highlight of the fair presentation is undoubtedly the “GAM 816”, which boasts impressive features. © Ideal-Werk

29.03.24 – Joining / welding

Joining / welding

Participants at the Wire Association’s 2023 International Technical Conference in Monterrey, Mexico: seated (l-r) Wire and Cable Executive panelists Andres Guerra Siller, DeAcero; Wesley Rios, Viakable; and Felipe Martinez, Kobrex. Standing (l-r) organizers Antonio Ayala, AA Enterprise; and Raúl Garcia, Viakable; and moderator Kurt Breischaft, SDI La Farga Copperworks. Not pictured: organizer Eugenio Urbina, Troester. © WAI

27.11.23 – On our own account - WIRE

On our own account - WIRE

All “DSH” type wire butt welding machines are already equipped with a device for post annealing of low carbon steels as standard. © Ideal-Werk

20.11.23 – On our own account - WIRE

On our own account - WIRE

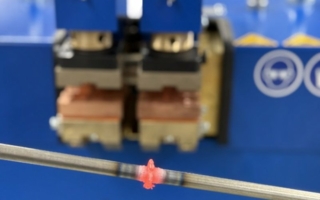

With the double pressure welding machine “DD0 104” the heat-affected material made of iron or non-ferrous metal is almost completely pressed out of the welding zone with force after the welding process. © Ideal-Werk