19/02/2021

An alternative to buying a new machine

In some instances, a general overhaul can be an alternative to buying a new machine. In which cases does this make sense and in which not? The tube bending machine manufacturer Schwarze-Robitec provides an overview.

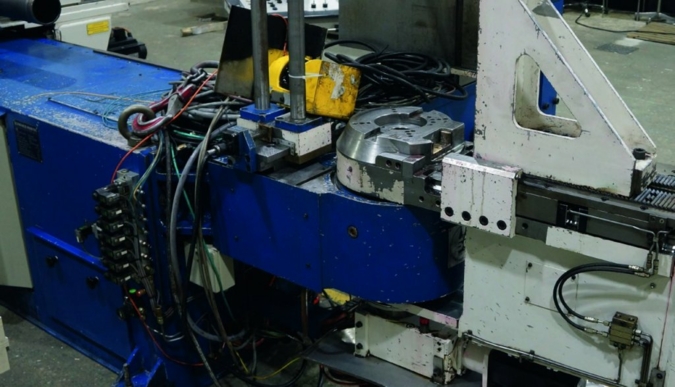

Since expensive parts such as the machine frame and welding components are re-used, an overhauled machine is roughly one-third cheaper than a new machine. © Schwarze-Robitec

Since expensive parts such as the machine frame and welding components are re-used, an overhauled machine is roughly one-third cheaper than a new machine. © Schwarze-Robitec