While the “No Twist Coiler” will be a key focus, Lämneå Bruk will also showcase its expertise in fully automatic lines. © Lämnea Bruk

While the “No Twist Coiler” will be a key focus, Lämneå Bruk will also showcase its expertise in fully automatic lines. © Lämnea Bruk

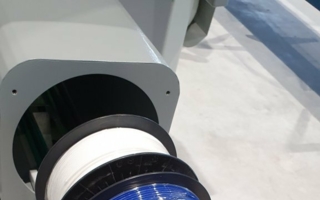

This year, Windak is focusing on technological advancements and sustainability in cable packaging. © Windak

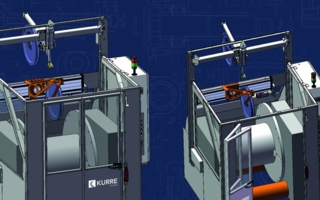

The increase of the bobbin load up to 2.5t as well as the floor-level loading of the new flange-driven winder are just a few advantages besides cost efficiency. © Kurre Systems

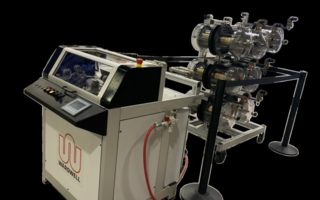

Wardwell also offers static payoffs for 150mm, 200mm and 250mm single end spools to feed the winders. © Wardwell

The “Fully Automatic Precision Layer Winder” is now available for 30kg, 15kg as well as smaller 5kg and 1kg spools. © Lämnea Bruk