16/06/2022 – Flat, Planetary and Circular

Thread rolling techniques

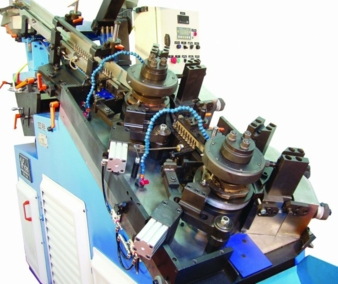

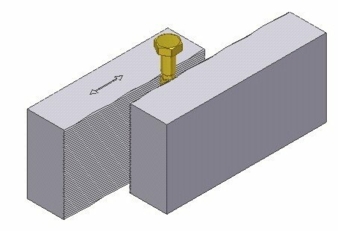

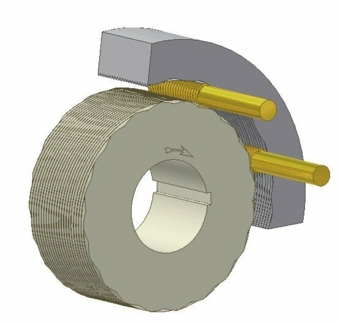

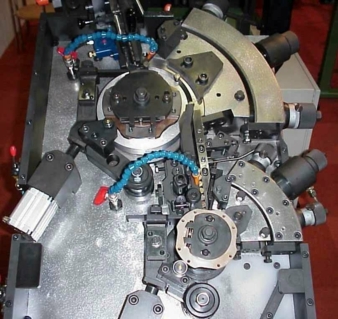

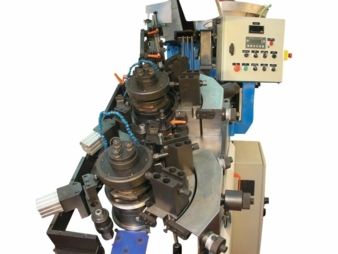

This article will compare between the 3 most common thread rolling systems: Flat-Die machines, using two flat thread rolling dies, Planetary (Rotary) die machines, using one circular die and one segment die, and Circular Die (2-Roll) machines, using two circular dies.