16/06/2022 – Flat, Planetary and Circular

Thread rolling techniques

This article will compare between the 3 most common thread rolling systems: Flat-Die machines, using two flat thread rolling dies, Planetary (Rotary) die machines, using one circular die and one segment die, and Circular Die (2-Roll) machines, using two circular dies.

Each threading system has advantages and disadvantages and the decision which system is best depends on the thread diameter and length, material hardness, batch size, budget and required accuracy. The question is therefore which system will yield the best result and be more cost effective?

Flat die machines

Flat die machines are the most conventional system for rolling threads. The flat die machines are simple to use and set-up and the thread dies are inexpensive. However, most machines are quite slow and have high maintenance costs due to the need to overhaul the ram every few years to keep the accuracy.

The number of revolutions that a blank passes in between the dies determines the thread quality and die life. A good number of revolutions is 6, while harder blanks need more revolutions and softer parts require fewer revolutions. The die size has a considerable effect on the machine size and cost, and for this reason, in most flat die machines, the blanks will turn fewer

revolutions then on any other system. The number of revolutions will have bigger effect on larger thread sizes, over M-10. The thread length in flat die machines is also restricted by the size of the machine. Thread length on flat die machines is usually in the range of 60mm - 100mm, with some machines on the market going up to 150mm. Flat dies are usually inexpensive, and are especially worthwhile to use when rolling complex forms, wood screw threads, etc.

Circular Die (2-Roll) machines

Circular Die (2-Roll) machines are divided into two categories:

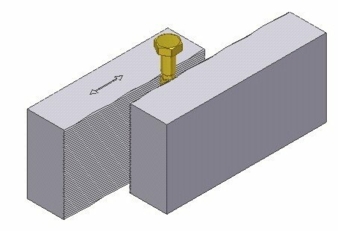

– Plunge-Feed (In-Feed) machines, where the two dies are parallel to each other and the blank is rolled between the rolls that close on it while rotating and form the thread.

– Through-Feed machines, where the blanks are fed into the dies while the dies are usually closed. The blanks enter the dies from one side and leave the dies from the other side, threading the part all along.

It is possible to use the through feed machine for partial threading by opening the dies after the blank has passed the required thread length.

Plunge-Feed machines have no restriction to the number of revolutions of the parts in between the dies and they are, therefore, used for rolling hard materials and parts that require more revolutions of the blanks in between the dies. Some Plunge-Feed machines are equipped with CNC control, which allows to change the roll speed in the various stages of thread rolling, thus enabling to start rolling in slow speed and increase the speed once the blank is firmly gripped in between the dies.

Through-Feed systems are used for rolling unlimited length and is practically the only available system on the market for rolling long threads. Through-Feed machines are available with either parallel shafts or tilting shafts. The parallel shafts accept thread rolling dies with a helix angle while the tilting shafts can accept either dies with parallel rings or speed-up dies with a helix angle, for faster feed rates.

Some Circular-Die machines can be used in both Plunge or Through- Feed modes, and also in a combined Plunge-Feed and Through-Feed mode.

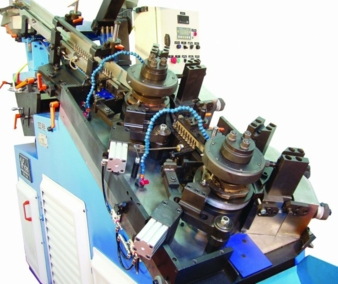

Planetary (Rotary) die machines

Planetary (Rotary) die machines are also divided into the following:

– Conventional planetary machines, which are mostly popular for fast rolling high volumes of machine threads in reasonable quality and low maintenance cost.

– New models with Controlled-Feed and Closed-Frame system, enabling to roll quality threads also on pre-hardened fasteners, as well. The Closed-Frame machines offer lower die cost-per-piece then on any other system.

Videx has been specializing in planetary machines since 1973. Recent developments in the feed system and machine construction, show impressing improvements in both thread quality and die life.

The Controlled-Feed mechanism is pushing the blanks in between the dies in at a perfect timing, and at a pre-determined speed, which is the speed of the rotary die.

In Flat Die machines the blanks are fed into the dies from a rest position when the ram is at the back position. To feed the blank, the ram moves forward and the blanks are accelerated to full speed in a fraction of a second. A flat die machine that rolls 300 parts per minute is actually performing 600 back and forth movements. At this speed, the whole stroke is completed in less than 0.1 second, meaning that the blanks are accelerated from rest to full speed in less then one hundreds of a second (0.01 second). Such acceleration results in some inevitable slippage between the threading dies and the blanks. This problem becomes more evident for larger and heavier parts.

A new model planetary machine that rolls 300 PPM is turning at 75 RPM and the line rolling speed of the blanks is only fractional to the speed of a flat die machine.

In most Circular-Die machines, the blanks also start from rest and are accelerated to full speed in a fraction of a second, creating the same trouble. Some CNC controlled modes are designed to slow down while the dies close on the blanks to overcome this problem.

In most old Planetary machines on the market, the blanks are fed into the dies starting from rest position.

To overcome the slippage problem, Videx has developed a mechanism that speeds up the blanks to the circumferential speed of the rotary die, so the blanks are fed in between the dies when they are already at the same speed as the rotary die, preventing such slippage.

The Videx Controlled Feed system also squares the blanks before feeding, making sure the parts are fed parallel to the threading dies. This feature is especially important for long parts or parts with heavy heads, etc.

Rolling long threads

Rolling long threads on Flat Die machines is restricted by the height of the die. Most flat die machines offer thread length up to 100mm, with few machines going up to 150mm. The higher die pocket requires the Flat Die machines to have a much heavier frame, resulting in a slower and more expensive machine, with higher maintenance costs.

Most Plunge-Feed machines are equipped with longer die pockets then Flat Die machines and are therefore more suitable for rolling long threads. However, the Circular Die machines are considerably slower then Flat Die machines, due to the fact that the parts are fed and ejected from above, requiring the operator (or in some cases the automatic feed system) to wait with the next blank until the part in process has been ejected.

Through-Feed machines are faster when rolling fully threaded parts that are fed one after the other.

When rolling long threads on headed parts or when the thread is not rolled on the entire length of the part, the parts can be through fed into the machine until the desired length is achieved and then the dies open. The disadvantage of this mode is that the last few pitches are incomplete because the blank is not rolled through the entire die.

In Planetary machines, the parts enter the dies from one side and leave the dies on the other side, so rolling long threads requires long die pocket and longer spindle.

Most conventional planetary thread rollers on the market offer 80-100mm thread length because longer die pockets are more complicated due to the deflection of the spindle and a thicker main spindle is more expensive and usually requires using more expensive dies.

The spindle in the new planetary “VA-ES” models is supported on both ends, quite similar to the construction of Circular-Die machines. This closed-structure offers the advantages of the Circular-Die machines with the speed and reliability of the planetary system. With the supported spindle, the VA-ES have practically unlimited die pocket, and Videx has already sold machines with 200mm and 300mm die pockets.

Data collected on die life when rolling long threads shows an increase in die life up to 4 times comparing to conventional planetary machines. The increase in die life is most evident when rolling hi-tensile fasteners.

Videx is offering dual and triple spindle machines for Wheel Bolts and Dual-Side bolts with two different threads. The machines can also roll grooves, chamfers and knurls prior to thread rolling.

Advantages and disadvantages of all 3 systems

Cost of rolling per piece: Flat dies cost less and roll fewer parts per set, compared to circular or planetary dies, requiring a more frequent change of the dies and more down time of the machine. When thread rolling small diameters up to M-5, the cost per piece may be the same or even cheaper on Flat dies. For larger diameters and higher tensile, the cost per piece in the Controlled Feed and Closed-structure Planetary models is 1/2 to 1/5 then the rolling cost per piece on flat dies.

Reliability and Maintenance: Flat Die machines should be overhauled from time to time to keep them running accurately. For this reason, they are the most costly in maintenance with the longer down time of all systems. Circular Die machines require little mechanical maintenance but some of them have hydraulic systems and front bearings which may require maintenance. The new models of Planetary machines have no slides and no hydraulics and therefore require very little to no maintenance. The main spindle runs inside taper roller bearings that can be tightened from time to time thus the machine keeps its accuracy even after 20 years of operation.

Speed: Planetary systems are 2-3 times faster than Flat Die machines and up to 10 times faster then Circular-Die machines.

Set-up time: The set-up time is comparable on all 3 systems when using appropriate tooling. Circular-Die machines using automatic feeding systems may take longer to set.

Rolling Hi-Tensile fasteners: Circular-Die machines offer unlimited number of revolutions and are therefore ideal when rolling parts harder then 40 Rc. Planetary closed-structure machines will yield the best “price per piece” ratio of all 3 systems. When rolling larger threads, the Planetary Die system offers in average, 50% more revolutions of the part in between the dies compared to Flat Die machines.

Threading complex shapes: Flat die machines are the most practical solution for rolling complex shapes in low and medium tensile fasteners because the dies are the simple to design and make. When rolling hi-tensile parts, Circular Die machines will have an advantage due to their ability to roll more revolutions on the part. Planetary system is ideal for threading and knurling but has no advantage when rolling complex shapes.

Rolling long threads: The Videx closed-structure models are available with die pockets up to 300mm, and are the most efficient and inexpensive way to roll long threads in larger and medium size batches of production. Circular Die machines are also available with long die pockets and are a good solution for small quantities.

Thread quality: Good quality machines will roll good quality parts. The Videx Controlled Feed system assures perfect thread quality also for hard to feed parts.

Machine cost: When comparing complete machines with their feed systems, the planetary machines will cost less than a good flat die machine or even a Circular-Die machine.

Compared to inexpensive Far-East machines, the planetary machines will pay for the difference in cost in less then a year just by the saving in die life. The longer the customer keeps the machine, the more saving he will have due to the no maintenance needs in the planetary machines.

Production: Planetary machines will run twice as fast as a Flat Die and up to 10 times faster then a Circular-Die machine.

Floor space & power consumption: Planetary machines require less floor space and ½ the power consumption per piece compared to Flat Die machines as it has no back stroke and further less power then Circular-Die machines which need to open and close with noisy hydraulics.

Process Monitoring: Flat die machine and Planetary die machines are using different models of monitors, but in both systems it is possible to control the thread quality just as good.

Orientation: In Plunge-Feed Circular Die machines, the parts are fed into the dies and out of the dies from above, thus requiring a special feed system. In Planetary machines, the parts get into the dies in one side and leave the dies on the other side, already oriented for the next production step. This feature allows combining the thread rolling system

with other operations as part of a line and allowed Videx to produce the multiple spindle machines for headed parts and the fully automatic machine working from coil.

In Flat Die machines the parts also get into the dies in one side and leave the dies on the other side, but due to the movement of the ram, the parts can not be oriented.

Floor Space: The planetary machines require less floor space then any other system.

Videx Machine Engineering Ltd.

20 Shabazi St., Yahud 5623107, Israel

Contact person is Yair Wiesenfeld

Tel: +972-3-536-4801

vyair@videx.co.il

www.videx-machines.com