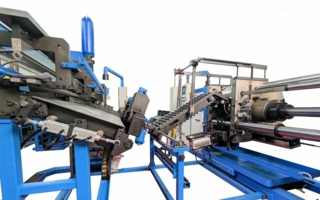

A thread roller for hardened fasteners with a computerised-match (can be see in operation at wire 2026). © Videx

04.03.26 – Cold forming / fasteners

Cold forming / fasteners

There is an increasing demand in the market for thread rolling of pre-hardened fasteners and at the same time there is a severe shortage of qualified operators, ...