22/09/2021 – Wire tensile strengths of up to 1,600N/mm²

Straightening technology for spring wire

Eurobend GmbH has more than three decades of experience in the construction of CNC-controlled straightening machines and systems for the wire and reinforcing steel industry.

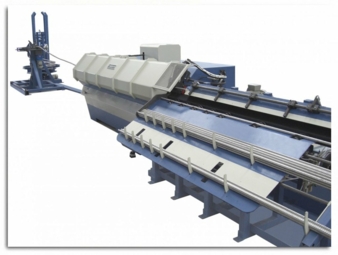

Model “MELC Monoline 12-25”: straightening machine with mechanical stop length measuring system for spring wire diameters up to 25mm. © Eurobend

Model “MELC Monoline 12-25 MS”: cutting length accuracy of ±0.1mm, independent of length. © Eurobend

Model “MELC Monoline 15-30”: Rotor straightening machine with electronic measuring system and robotic coil opening system for diameters up to 30mm. © Eurobend