Fig. 1. Resulting from 40 years of experience in the springs world, the machine is designed with manual spring feeding. © Easydur

Fig. 1. Resulting from 40 years of experience in the springs world, the machine is designed with manual spring feeding. © Easydur

The market for drawn wire for spring applications is demanding and constantly evolving. © Swiss Steel Group

With a finished tensile strength of 2000MPa the handling specifications have been further developed to accommodate this increased requirement by manufactures. © Inductotherm Heating+Welding

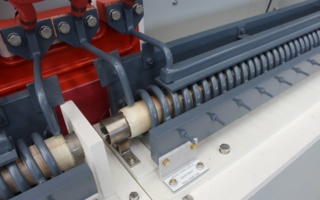

Model “MELC Monoline 12-25”: straightening machine with mechanical stop length measuring system for spring wire diameters up to 25mm. © Eurobend

The CWI alloys, available in stainless steel, nickel and copper, can be made into durable, corrosion resistant springs. © Central Wire Industries