24/08/2020 – Surface treatment

Spring into action

Technical springs are key, safety-relevant components in the motor vehicle sector. As a result, effective corrosion protection of these parts is essential. Zinc flake systems from Dörken Coatings are therefore particularly well suited to the coating of technical springs.

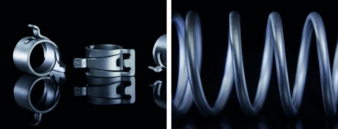

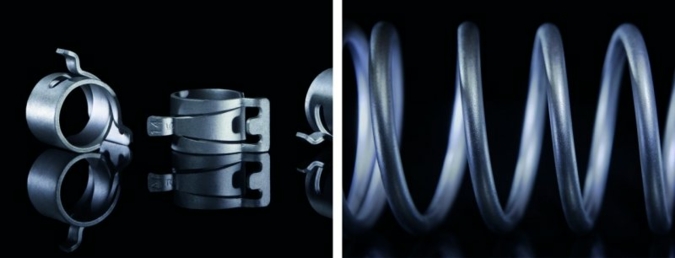

Zinc flake systems are suitable for coating springs and spring band clips, offering effective corrosion protection. © Dörken