24/08/2020 – Surface treatment

Spring into action

Technical springs are key, safety-relevant components in the motor vehicle sector. As a result, effective corrosion protection of these parts is essential. Zinc flake systems from Dörken Coatings are therefore particularly well suited to the coating of technical springs.

All functional elements of motor vehicles are subjected to extreme stresses. Potholes, cracks or unevenness on the roads are hard on the chassis parts, with high quality a subsequent prerequisite. To avoid these problems, in addition to different forms of arms and rods, cars also require various types of springs. These play a major role in the complex chassis system and have two elemental tasks: on the one hand, they are responsible for vertical vibration behaviour. This means that, in combination with other components, they compensate the unevenness of the road, ensuring a high level of ride comfort. On the other hand, springs ensure that the wheels are in constant contact with the ground – regardless of the condition of the road surface. This results in drive, braking and transverse forces being transferred safely between road and vehicle at all times.

In addition to mechanical stresses, springs also need to withstand the influence of water, heat and particle friction such as salt or grime. Surface protection is particularly important when it comes to preventing possible corrosion damage. Technical springs are notch-sensitive components in which even a small amount of corrosion can result in fracture. The result: broken springs affect the balance of the vehicle and therefore have a negative influence on braking and tracking stability.

An effective coating is therefore all the more important. This needs to be specially adapted to the respective spring. In addition to the type of steel used, aspects such as pre-treatment, temperature stress, coat thickness and the geometry of the springs consequently need to be considered.

In the choice of suitable corrosion protection, for high-tensile steels in particular it is especially important that no hydrogen enters during the coating process, as this would significantly inhibit the properties of the springs and, with increasing tensile strength, result in cracks and fractures. In addition, specified maximum temperatures also need to be observed in the annealing process. If the annealing temperatures are reached again or even exceeded in the surface treatment process, the residual compressive stress of the springs could be lost. This would render the component unable to function.

Proven solution

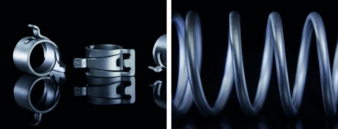

Zinc flake systems from Dörken Coatings are therefore particularly well suited to the coating of technical springs. One advantage is that they are suitable for springs of all geometries - whether they are compression, plate, spiral, leaf or parabolic springs. Reasons for this include good penetration and the particular creep ability of the solvent-based zinc flake systems frequently used for the coating of springs. This enables all surfaces and gaps to be reached and coated evenly, even in parts with complicated geometry. Further advantages are the active cathodic corrosion protection, the material-saving coating process and annealing at low temperatures In addition, good ductility is also provided, which is of particular importance for springs.

The coating

The protective coats are typically applied at a thickness of between 6 and 25 µm and enable very high corrosion durability of up to 1,000 hours in salt spray tests in accordance with DIN EN ISO 9227. As a rule, the coating systems comprise a base coat and an organic or inorganic top coat. Both coats are annealing systems that are chemically cross-linked at temperatures of between 180–250°C. The zinc flake system is a largely inorganic, micro-layer-forming base coat on the basis of zinc and aluminium flakes, which offers active cathodic corrosion protection – including after stone impact. This means that in the event of damage to the coating the ignoble zinc in the base coat sacrifices itself on contact with water and oxygen in favour of the more noble steel base material. A subsequently added top coat can further enhance corrosion protection significantly. In contrast to the base coat, this is not electrically conductive. Depending on the choice of top coat, further requirements such as colouring and chemical resistance can also be met.

The choice of coating technique is also dependent on the respective component. Zinc flake coatings are applied using standard application processes and subsequently annealed. The dip-spin method is typically used for bulk parts, with spraying for larger components.

Conclusion

Zinc flake systems offer numerous benefits for springs of all kinds: high corrosion durability, an even coating, even for parts with complicated geometry, low annealing temperatures and the avoidance of application-related hydrogen-induced stress corrosion cracking.

Dörken Coatings GmbH+Co. KG

Wetterstrasse 58, 58313 Herdecke/Germany

Tel.: +49 2330 63-243

coatings@doerken.de

www.doerkencoatings.de