14/09/2020 – Wire straightening

Rethinking in wire straightening

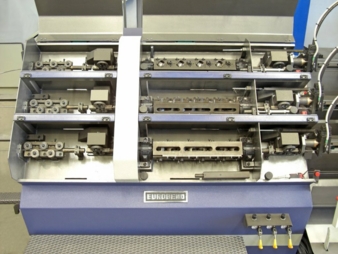

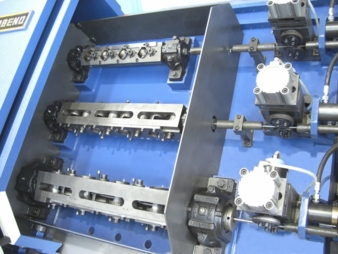

This straightening machines concept works with multiple, simultaneously working rotors with hyperbolic rollers. Eurobend offers multi-line wire straightening machines with simultaneously operating straightening rotors – the “MELC Polyline” series.