08/12/2020 – Joining / Welding

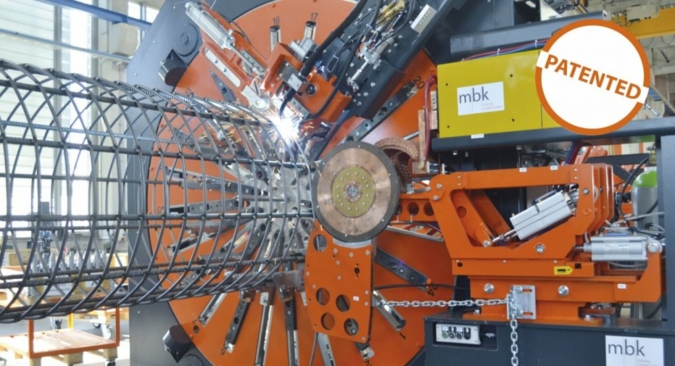

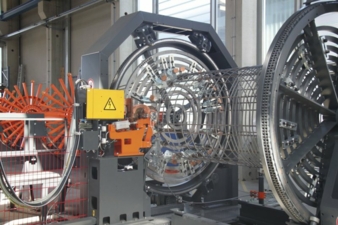

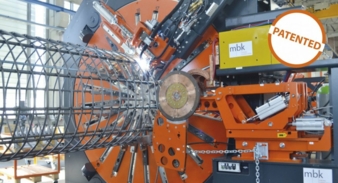

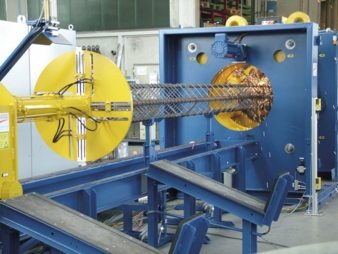

Cage welding machines for driven and bored piles, columns and beams

When ground conditions are difficult and a firm foundation has to be created, this is the time for pile foundations and bored piles. There is also great demand for precast driven concrete piles, ranging from simple halls to extremely complex constructions.