08/12/2020 – Joining / Welding

Cage welding machines for driven and bored piles, columns and beams

When ground conditions are difficult and a firm foundation has to be created, this is the time for pile foundations and bored piles. There is also great demand for precast driven concrete piles, ranging from simple halls to extremely complex constructions.

Reinforcements in a wide range of dimensions form the basis for all these driven and bored piles, columns and beams. When special designs and gigantic dimensions are required, one name is at the forefront of the industry: MBK Maschinenbau GmbH has long been known as a system solution partner. Individual concepts with added value are created with a high level of technical know-how, a great deal of experience, immense innovative power and the ability to fully engage with the concerns of the customers.

For the production of round and square reinforcements for driven and bored piles, columns and beams, MBK has cage welding machines with different specifications in its product range.

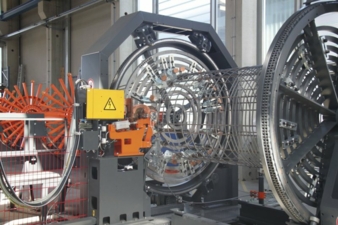

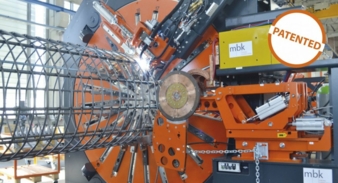

ASM cage welding machine

The ASM cage welding machine, which was designed for the flexible production of reinforcement for driven and bored piles, columns and girders, is capable of producing cages with an outer diameter of up to 2,100mm (depending on the number of longitudinal wires and wire combinations) and a maximum length of 24,000mm. The longitudinal wire diameter is 12mm to 25mm (optionally 12mm to 32mm), the diameter for winding wire is 6mm to 12mm (optionally 6mm to 16mm).

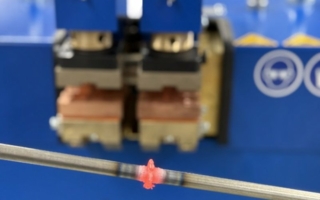

Various welding processes are possible with the ASM: resistance welding, single and multiple inert-gas welding and the patented “Dual Weld” – the flexible, dual welding concept that combines the advantages of both systems. With Dual Weld it is possible to change between the welding processes or to weld in parallel.

A straightening unit for winding wire, a hydraulic cage support, winding wire reels with or without drive, various longitudinal wire diameters and asynchronous divisions in one cage are all components of the ASM. The LAN/WLAN connection, a touch screen with colour display and the setting of the reinforcement cage and welding data via stored programs are standard.

LSM, VSM-S and VSM-V cage welding machines

The LSM, VSM-S and VSM-V cage welding machines were developed for the production of round and square reinforcements for driven and bored piles, columns and beams.

LSM cage welding machine

The LSM is available in two sizes (084 and 150) and two types (R/S: R = round, S = round and square). For square cages of “LSM type S”, the outside flank length ranges from 90mm to 1,108mm, depending on the wire combinations. The outer cage diameter for round cages is between 170mm and 1,570mm, depending on the number of longitudinal wires and wire combinations.

Standardised cage lengths can be realised in the range from 3,000mm to 24,000mm; other lengths are of course available on request. The longitudinal wire diameter is 8mm to 25mm (optionally 8mm to 32mm), the diameter for winding wire is 5mm to 10mm (optionally 5mm to 16 mm).

“LSM-C” cage welding machine

The cage welding machine of the type “LSM-C” is predestined to produce round and conical reinforcements for masts, driven and bored piles, columns and beams. It is also available in two sizes. The outer cage diameter for round cages is max. 1,500mm, depending on the number of longitudinal wires and wire combinations. Standardised cage lengths can be realised in the range from 3,000mm to 24,000mm; other lengths are of course available on request. The longitudinal wire diameter is 8mm to 12mm, the diameter for winding wire is 5mm to 8mm.

With the cage welding machines from the LSM series, no consumption of inert gas and electrodes is necessary. The ergonomic handling on the wire and cage side makes working noticeably easier. Winding wire cutters with and without drive as well as electric wire cutters ensure an efficient production process.

The electronic welding point control achieves a very high welding capacity and welding quality - the precise dosage of the welding power, the contact pressure and the length of the respective welding impulses achieve very good results.

The possibility of setting reinforcement cage and welding data via stored programs is a great help in everyday production. The programmable winding wire pitch also ensures high variability. Easy handling and programming is guaranteed by the use of touch panels and IPC/PLC control. The LAN/WLAN connection is part of a modern production process.

The LSM can also be optionally equipped with the Dual Weld, the flexible, dual welding concept.

“VMS-S” cage welding machine

The “VMS-S” is distinguished by a number of features such as the performance package for higher welding and production capacities or the coil winder for winding standard coils onto LSM series coils.

For square cages of VSM type S, the outside flank length ranges from 94mm to 450mm, depending on the wire combinations. The outer cage diameter for round cages is between 132mm and 636mm, depending on the number of longitudinal wires and wire combinations.

The number of longitudinal wires is defined by replacement discs (variable). The maximum standard length of the cages is 3,000mm to 24,000mm and can be individually determined on request.

The quick-change system for different cage geometries (round, triangular, square, etc.) supports economical work. Very high flexibility underpins efficient production. This is made possible by the quick changeover of the machine to other geometries.

“VSM-V” cage welding machine

The “VSM-V” cage welding machine is used for the production of square reinforcements for driven and bored piles, columns and beams. It only differs from the VSM-S in the manufacturing dimensions, the characteristics are identical.

For square cages of VSM type V, the outside flank length ranges from 111mm to 422mm, depending on the wire combinations. Cage lengths as for the VSM-S, i.e. 3,000mm to 24,000mm, including the possibility of individualisation. 4 longitudinal wires, optionally double wire in the corner.

Automation solutions are available for the VSM series, ranging from simple automation accessories to fully automated production lines with buffer solutions.

VSM-S automation solution

In the case of the VSM-S, the automation solution includes longitudinal wire storage systems for the pre-assembly of the wires from the coil as well as the connection of a multiple wire straightening and cutting system (DRA-M) for the pre-assembly of the longitudinal wires, and a simplified quick-change system for the geometry changes using product discs. Other possible solutions include a processing system after the removal of the reinforcement, the automatic removal of the finished product for further processing and a buffer storage system with positioning of the products.

VSM-V automation solution

The VSM-V is also equipped with the DRA-M (wire straightening and cutting machine for wire diameters up to 20mm) as part of the automation for the pre-assembly of the longitudinal wires. Quick adjustment to reduce changeover times when changing diameters is also part of the automation, as is the fully automated conversion of all relevant systems to other product sizes and the integration of a longitudinal wire feeder for welding a tight coil with short longitudinal wire projection. A chain conveyor as a buffer and for feeding the longitudinal wires into the machine (automatic loading also possible via DRA-M) and the processing station after removal of the reinforcement are sequences of the VSM automation. The automatic removal of the finished product for further processing and the buffer storage system with positioning of the products for removal complete the automation spectrum of this series.

“RSM” cage welding machine

The “RSM” cage welding machine is used to produce round and square reinforcements for driven and bored piles, columns and beams with or without cones. They are available in the versions V and S, where V stands for square, single, double wire in the corner and S for round, square, optional double wire in the corner for square.

For square cages of RSM type S, the outside flank length ranges from 92mm to 422mm, depending on the wire combinations. The outer cage diameter for round cages ranges from 130mm to 596mm, depending on the number of longitudinal wires and wire combinations.

The number of longitudinal wires is 4, optionally double wire in the corner. The cage length impresses with dimensions of 3,000mm to 18,000mm, other sizes are available on request.

The RSM convinces with many features such as a very high variability in the winding wire pitch (multiple production of short cages in one long cage is also programmable), the production of cages with a taper (cone) by means of pre-bent longitudinal wires, the possibility of double wires in the corner and the manual adjustment of the diameters. The RSM also eliminates the need for inert gas and electrodes. The cage welding machine also convinces many users with its easy handling, the setting of the reinforcement cage and welding data via stored programs, low maintenance and the LAN/WLAN connection. Further automation solutions are also available on request.

MBK Maschinenbau GmbH

Friedrich-List-Strasse 19

88353 Kisslegg/Germany

Tel.: +49 7563 91310

info@mbk-kisslegg.de

www.mbk-kisslegg.de

About the company

MBK is a specialist for the production of wire cage welding machines and can react with its design team to an innovative market with enormously short development cycles. MBKL’s strength lies in being fully committed to special customer requirements and responding with a high degree of individualisation with corresponding solution concepts. The company from Kisslegg/Germany is a leading manufacturer of welding machines and systems for the reinforcing steel processing industry as well as the construction and precast concrete industry. Customers in over 60 countries around the world appreciate this.