16/11/2022 – „Eddyeyes“ – vision and artificial intelligence

AI to classify defects automatically

Gone are the days when defects were detected with eddy current coils and the results had to be interpreted with varying degrees of expertise by the inspector. This does not mean that eddy currents are not valid; on the contrary, they are still the main inspection technology for hot-rolled long products. No other is as reliable, as economical and as widespread.

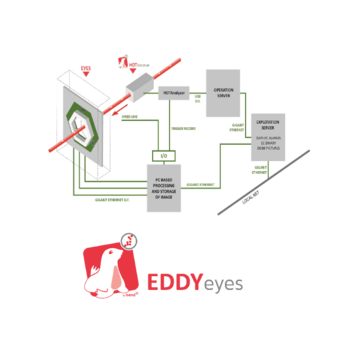

Today, the key to quality control of this type of product is the use of artificial intelligence (AI) to classify defects automatically with high percentages of accuracy. © Isend