18/10/2025 – The double pressure welding (DD) process for non-ferrous metals

Efficient and high-strength joints

In modern manufacturing technology, the joining of non-ferrous metals such as aluminum, copper, and other alloys is becoming increasingly important. Especially in industries like electrical engineering, automotive, and machinery, reliable and high-strength welds are in demand.

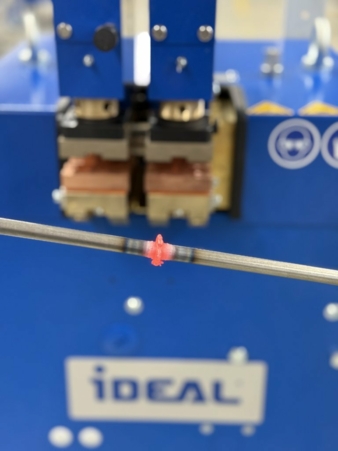

The double pressure welding (DD) process offers an innovative solution to significantly improve the mechanical properties of welds.

What is the double pressure welding (DD) process?

The DD process is a specialized welding technique that can be implemented on certain machines, such as models “DSH 130” and new “DSH 250”, equipped with the NE configuration. During welding, an additional pressing stroke is performed, which has a substantial influence on the welding process.

How it works and its benefits

During welding, the heat-affected material in the weld zone is almost completely expelled from the joint due to the extra pressure. This process results in a refinement of the grain structure in the heat-affected zone, which in turn significantly enhances the mechanical properties of the weld seam.

The key advantages of the double pressure welding process include:

– refined grain structure: Grain refinement increases the strength and toughness of the weld.

– high tensile strength: The joints are extremely durable and suitable for high-stress applications.

– high bending strength: The welds reliably withstand bending stresses.

Applications

The DD process is particularly suitable for processing non-ferrous metals where high mechanical demands are placed on the joints. It is used in manufacturing cable connections, electrical conductors, and finds applications in the automotive and aerospace industries, where durable and reliable joints are essential.

Conclusion

The double pressure welding (DD) process represents a significant advancement in welding technology for non-ferrous metals. Through targeted grain refinement and additional pressure, it creates high-strength, reliable joints that meet the demands of modern industrial applications. Companies committed to quality and durability in their welds can benefit greatly from this innovative technology.

Cable & Wire Fair 2025, booth 3/Q2-1

Ideal-Werk C.+E. Jungeblodt GmbH+Co. KG

Bunsenstrasse 1

59557 Lippstadt/Germany

Contact person is Michael Tieze

Tel.: +49 2941 206-111

tieze@ideal-werk.com

www.ideal-werk.com