02/03/2023 – Research / Wire manufacturing

Sustainable wire production through recycling

The constantly growing global challenges require the responsible and economical use of available resources. One possibility to reduce the energy demand in wire production is the friction-induced recycling of presumed rejects and scrap.

Not only the current global crises and challenges, but also the advancing climate change require a responsible and economical use of natural resources and energies. One way to improve energy and resource efficiency is to recycle presumed rejects and scraps. The conventional (smelting metallurgical) recycling process for processing aluminium scrap is already a significant improvement compared to the primary manufacturing route. However, a comparatively large amount of energy is still used for aluminium recycling and scrap products such as salt slag have to be processed at great expense. A solution to this problem is the use of solid-state recycling processes using a processing temperature that is significantly lower than the melting temperature of the aluminium. As a result, less thermal energy has to be introduced into the entire recycling process, which provides an energetic advantage over conventional manufacturing strategies for aluminium products.

Process principle

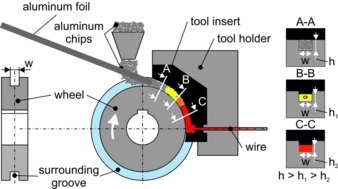

As an example of a solid-state recycling process, the friction-induced recycling process has been researched at the University of Paderborn for several years with the aim of producing a sustainable as well as high-quality wire from supposed rejects. The operating principle of the process is shown in fig. 1. The rejects (e.g. aluminium chips or aluminium foil) are continuously fed into the rotating wheel groove. Due to the continuous reduction of the wheel cross-section, the particles are compacted, reshaped, heated and plasticised. Following the rotation of a quarter turn, the plasticised material is extruded through a user-specific die, analogous to the conventional extrusion process, to ensure further forming of the material. By exchanging the die (= shaping opening), both the geometry of the (in theory) endless semi-finished products and process variables such as the frictional heat generated in the process can be influenced.

Properties of the recycled semi-finished products

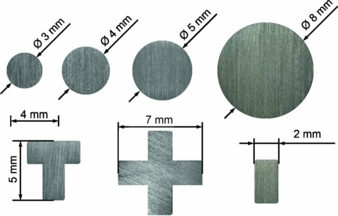

Within the scope of the investigations concerning the influencing factors of the process, it was possible to prove, among other things, that a large number of different semi-finished product geometries with good filling could be produced. A selection is shown in fig. 2. The central object of investigation was first of all the processing of different chip shapes of the wrought aluminium alloy EN AW-6060. In addition, other aluminium alloys such as the almost pure aluminium EN AW-1350, the cast alloy EN AC-43000 and the high-strength alloy EN AW-7075 were successfully processed. A hardness mapping over the cross-sectional area of the (continuous) semi-finished products shows that in the stationary process phase (production phase with constant process variables in the form of temperature as well as energy demand) there is a uniform hardness distribution. The (tensile) strengths of the recycled semi-finished products are comparable to those of conventional semi-finished products in a solution-annealed condition, which can be attributed to the process temperatures in the range of 300°C to 400°C. Future investigations should provide evidence that with a specific heat treatment the artificially aged condition with higher strengths can also be set for the recycled samples.

Energy comparison

With regard to the amount of energy required for the production of semi-finished aluminium products, the results of the friction-induced recycling process (approx. 10 MJ/kg) were compared with those of primary aluminium production (based on bauxite mining approx. 160 MJ/kg) as well as the smelting metallurgical recycling process (approx. 17.7 MJ/kg) (see also [1]). In addition to the considerable energy-saving potential of the friction-induced recycling process, no toxic salt slag is produced and the process chain can be significantly shortened based on the direct production of the recycled semi-finished products.

This research was partially funded by the state of Northrhine Westfalia via the Forschungskolleg “Leicht-Effizient-Mobil” (LEM).

[1] Borgert, T. and Homberg, W. (2022). Energy saving potentials of an efficient recycling process of different aluminum rejects. Energy Reports, 8, 399–404. https://doi.org/10.1016/j.egyr.2022.01.027

The authors are Thomas Borgert and Werner Homberg

Forming and Machining Technology (LUF) Paderborn University

Pohlweg 53, 33098 Paderborn, Germany

Contact person is Thomas Borgert

Tel.: +49 5251 60-3168

tb@luf.uni-paderborn.de

www.luf.uni-paderborn.de