02/03/2023 – Research / Wire manufacturing

Sustainable wire production through recycling

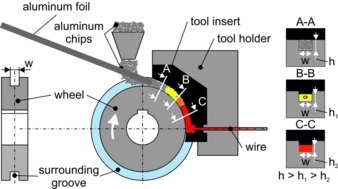

The constantly growing global challenges require the responsible and economical use of available resources. One possibility to reduce the energy demand in wire production is the friction-induced recycling of presumed rejects and scrap.

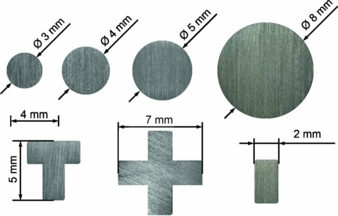

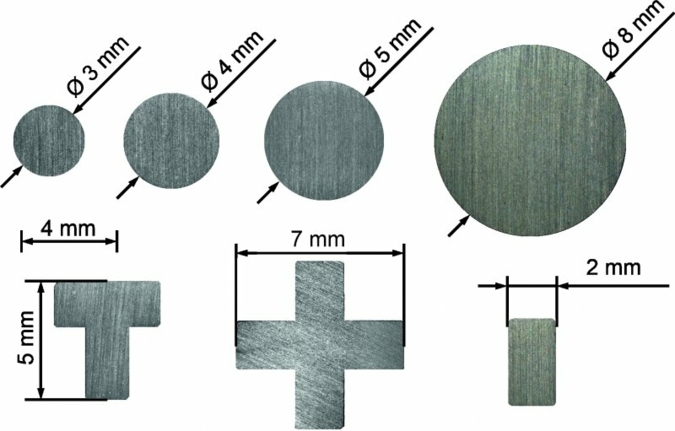

Fig. 2: Typical semi-finished product geometries that were successfully produced using the friction-induced recycling process. © LUF