08/09/2021 – Wafios “ZO” series

The legend lives on

The “ZO 26” is the advanced version of the gobally successful Wafios “ZO” machines for the series production of extension springs with different loop shapes of up to 1.6mm wire diameter.

Based on decades of experience the machine concept has been completely redesigned . It now stands for maximum reliability and highest outputs in the production of extension springs while ensuring 100% quality control. The standard “ZO 26” machine consists of a coiling machine and a directly attached construction for the bending of loops. The coiling machine has been designed for the production of right-hand coiled springs and features 3 axes (for the feed unit, the coiling unit and the straight cut). The directly attached structure consists of two transport turrets with 4 axes (2x stroke / 2x rotation) and an additional transfer station (for the bending of loops, for measuring). The 2-channel sorting device is included in the standard machine. Looping plates and tools from previous machines are compatible with the new ZO machine making the switch to this new, more powerful machine technology a safe investment.

Enhanced extension spring production process

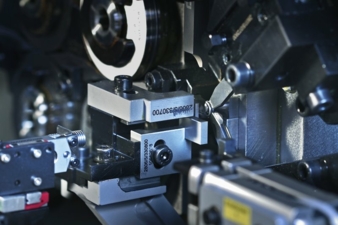

First of all, the spring body is coiled by the coiling machine that is based on the Wafios “F” series, a size 2 performance machine with functions optimized and adjusted to the production of extension spring bodies. The standard version of the coiling machine is equipped with 3 CNC axes which are responsible for wire feeding, cutting and shaping. The quality of an extension spring and the position and dimensions of its loops depend on the accuracy of the spring body. Here the ZO 26 benefits from the high degree of repeat accuracy Wafios spring coiling machines are famous for.

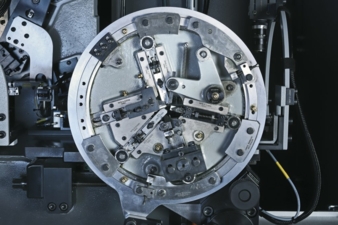

The newly developed spring transport unit of the extension spring coiler then transfers the spring body from the coiler to the first looping station. The looping machine is a directly attached construction located before the coiling machine. The machine's compact design is of advantage as the travel paths for transferring the spring body are short and all looping stations are well accessible.

Once the first loop has been set upright, the extension spring strand is transported to the next station where the loop can be trimmed, if necessary. Regardless of whether a trimming process is carried out or not, the geometry of the first loop is checked by camera measurement. After a second transport system has picked up the spring, the second loop is produced in the same way in separate stations (setting the loop upright, trimming the loop and optical control). This unique principle of producing loops in separate stations guarantees a maximum output of extension springs with the highest quality of loops. Another advantage is the production of different loops on both ends of the extension spring strand.

High-speed production of up to 80 extension springs per minute

The reliable looping plate technology guarantees a flexible production of loop shapes. It can be set up outside the machine. The ZO 26 offers a higher range of applications than comparable machines on the market. Many different kind of loops can be produced. The standard ZO 26 comes with a set of tools for the production of machine loops, simple loops, double loops and laterally set up loops. At any time, the machine can be set up with auxiliary devices and according tools for the production of crossover loops and widened loops.

New, cost-optimized design of looping plates for better handling and accessibility

The looping plates are used to set up the first / last coil in order to form the spring loops. The sophisticated and well-proven looping plate technology has been revised and enhanced in terms of the set-up of loop geometries, operating convenience and tool set-up. This includes the simplified set-up and readjustment of loops in case of deviations, e.g. due to tool wear. There are no reciprocal effects between the mechanical set-ups of the looping plate which makes it easier for the operator to make specific adjustments.

The use of holding tools enables the production of short spring bodies

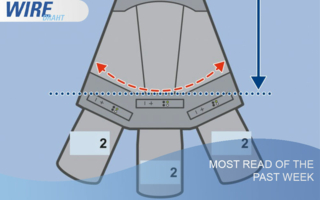

Contrary to the conventional ZO machine from the past with two turrets rotating counter-clockwise, turret number two now rotates in the opposite direction and the spring is transferred via a fixed stop. This also enables the production of shorter spring lengths and makes the entire transfer procedure a lot easier.

The springs are transferred from turret 1 to turret 2 in the transfer station by holding tools that are thrust in and out. Contrary to pneumatic grippers, these holding tools only need very few coils for safely holding the spring. Therefore, also extension springs with only a few coils can be produced without any problems.

Quality without compromise

The spring loops are optically measured to ensure maximum quality. The integrated camera systems measure and check each loop's height and opening size. Defective parts are sorted out via the 2-channel sorting device (100% control). With the optional trimming plates, each extension spring can be trimmed to a defined opening size. This ensures highest accuracy of springs which is particularly important when there is little space available for installing the finished extension springs.

Numerous options enable a customized equipment of the Wafios ZO 26. Available options are: parallel pitch device, pneumatic mandrel displacement, scanning device, trimming plate, devices and tooling for the production of crossover loops, device for widening loops as well as a force measuring device and a servomotor-driven spring guide.

2nd Reutlingen E-Mobility Days (RED), October 18-29, 2021 in Reutlingen/Germany

https://emobility-days.wafios.com

Save the date: Wafios “Innovation Days” in Reutlingen/Germany on September 13 - 17, 2021.

https://innovation-days.wafios.com

Wafios AG

Silberburgstrasse 5

72764 Reutlingen/Germany

Tel.: +49 7121 146-0

sales@wafios.de

www.wafios.com