27/10/2025 – Monitored sorting device – for reliably identifying good springs

Separating the wheat from the chaff

Every last detail counts in industrial spring production. Customers expect the very highest standards of quality and consistent geometry – and manufacturers promise to meet these demands.

However, technical challenges often stand in the way of making those promises a reality. One example of these is ensuring that good and bad springs are reliably sorted. With its new electrically driven and sensor-monitored sorting device, Wafios offers an innovative solution that not only improves the sorting process but also makes it verifiably more reliable.

The new electrical monitored sorting device from Wafios is proven to remove bad springs from production reliably.

“Pneumatic sorting devices have always been a standard option on Wafios machines. To handle smaller spring sizes, the new monitored 3-channel sorting device with electrical drive is now available for adding to the FUL 26+ and FUL 36+ in sizes 1 and 2,” says Dr. Uwe-Peter Weigmann, Speaker of the Wafios Board.

Not all sorting processes are made equal

Spring production has traditionally relied on pneumatic sorting devices. Although fast, easy to use and proven in practice, this equipment comes with some limitations.

As an example, the sorting process has never been entirely traceable as the flap positions are not continuously monitored. During this process, the flaps tend to rebound when they hit the sides of the sorting device, which can lead to incorrect sorting or jammed springs in some cases. This results in springs being sorted incorrectly and even damage to the sorting device itself. A reliable sorting mechanism that produces proven results is vital, especially in cases involving critical parts of the kind that can be found in the medical and automotive sectors, for example.

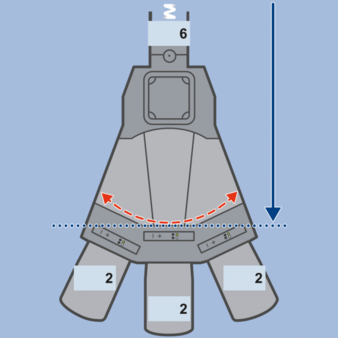

Pneumatic devices offer a practical technical solution for standard applications and are inexpensive to put in place. Featuring a bottom pivot point, their design is simpler but harbours some risks in that, if the flap has not fully reached the end point, springs can be impaled. This can result in defects and inaccurate sorting at high production speeds. In many of these cases, the operator ends up having to intervene manually – and this means that downtime is required.

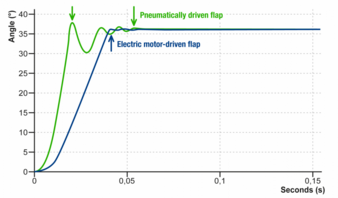

Electrically controlled sorting devices feature a flap pivot point at the top activate both flaps simultaneously using a single drive. This prevents springs from being impaled as a result. At the same time, the motor in the electrical sorting device keeps the flaps stable when it stops them, without any rebound – and has a slightly increased response time.

Sensor-monitored sorting for maximum process reliability

Modern sorting devices in spring production rely on comprehensive sensor monitoring to eliminate errors in the sorting process. Sensors in the drop-in area and at three discharge channels accurately determine the path of each individual spring. This allows the system to tell reliably whether a spring has been correctly sorted – and makes the sorting process more dependable. With this system, many errors that previously went undetected in the sorting process are now made apparent.

The sorting unit is set up on the basis of the production output and the spring drop time. The flap delay time used to be determined manually, but the new monitored sorting device now executes this task fully automatically. It uses the cutting time and the sensors at the start and end of the sorting path to calculate the perfect time to activate the flaps – for precise, reproducible results.

“To make the sorting process even more accurate, the sorting device also draws on the machine’s cutting time data. This means it can track the exact timing of the spring’s course – from the cutting point to its passage through the sorting device”, says Weigmann.

Intuitive operation and automatic error detection

When the sorting device is adjusted or restarted, it performs a reference run. During this, the flaps at both sides move to their furthest point and have their positions saved as reference points. If a position is not reached – because of a jammed spring, for example – the system detects the error and stops production automatically.

The sorting device system is fully controlled via the machine display in the Wafios Programming System “WPS 3.2 Easy Way”. In this, the operator can conveniently track the sorting process for each individual spring. This is based on the measurement of the drop time – that is, the time from the cut to the discharge sensor.

The sorting logic is based on two limit values: the maximum moving time of the sorting flap (red line) and the minimum cycle time of the spring (white line). If the drop time of a spring is below the flap movement time, reliable sorting can no longer be guaranteed – and the measurement point appears in red. If the drop time exceeds the minimum cycle time, on the other hand, this may mean that springs overtake or become entangled with one another, preventing them from being sorted accurately. In this case, the point appears in yellow.

Correct sorting is only possible if the drop time is between two limit values. When this happens, green appears to show the user that the process situation is stable. But what happens if multiple springs pass through the device at once? To keep quality at a high standard, the operator can activate or deactivate multiple sorting in the Wafios Programming System (WPS). With multiple sorting, the sorting device responds to a bad spring by removing all the springs that fall into the system along with the bad one.

Outstanding quality from beginning to end

The new sorting device will show on the “FUL” series what a modern 3-channel sorting device is capable of. The sorting device is motor-driven and controlled by the spring coiling machine control unit. Maximum reliability in the sorting process is achieved by monitoring the position of the flaps. During the correct sorting process, the dropping behavior of the springs is monitored by sensors. This increases production reliability because it prevents springs from jamming or an incorrectly positioned flap. Automatic setting of the delay time as a function of the drop time also ensures a smooth and reliable setup process. The monitored sorting device can also be retrofitted to existing machines in the “FUL+” series, including the “FUL 26+”, “FUL 36+”, “FUL 46+” and “FUL 56+”. This requires a “TwinCAT3” control unit plus a PLC and WPS update.

Wafios AG

Silberburgstrasse 5

72764 Reutlingen/Germany

Tel.: +49 7121 146-0

sales@wafios.de

www.wafios.com

Brief profile of Wafios

Wafios develops, designs and produces sophisticated, specialist machinery for the wire and tube processing industry and for cold-forging applications. The company is one of the world’s foremost providers in this field. More than 130 years of experience stand for quality and innovation. The range of products includes more than 130 types of machines. Equipped with the latest software, artificial intelligence and IoT, Wafios machines optimize the output, the quality and the setup process. 60% of Wafios’ customers work in the automotive and supplier industry, with a growing share in e-mobility. But the company also serves major industries such as mining, construction, electrical engineering, medical technology, household appliances, agriculture and furniture. Exports account for more than 60 percent of total sales. Today, Wafios has evolved into a group of companies that consists of parent company Wafios AG, based in Reutlingen, plus several locations throughout Germany (Reutlingen, Marktredwitz, Wuppertal, Berlin, Simonswald, Hilchenbach), France (Ecuelles), Portugal (Maia), the Americas (Branford/USA, Mokena/USA, Querétaro/Mexico, São Paulo/Brazil) and Asia (Shanghai/China, Zhangjiagang/China), providing customers with local support.

Wafios expands its core business with the “connectavo” brand, developing software solutions for maintenance work in such areas as machinery, building services engineering, vehicle fleets and other technical facilities.