02/03/2021 – Producing spoke blanks

Rolling instead of swaging

The booming e-bike market has led to a growing demand for butted spokes, i.e. spokes that are thicker at one or both ends. AMBA’s new gauge reducing machines achieve throughputs of up to 40 pieces per minute in spoke blank production – many times higher than the rates achievable by conventional machines.

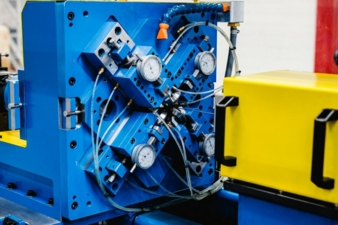

Thanks to the high-speed slides of the gauge reducing machine, throughputs of up to 40 spokes per minute can be achieved. © AMBA

Servo-controlled ball screws actuate the slides that pull the wire through the various processing stages of the machine. © AMBA