18/09/2023 – BLM Group introduces the new “VGP Next” software

Revolutionising the world of bending

“VGP Next” is the new CAD/CAM programming software for BLM Group tube bending and wire bending machines that tackles the latest technological challenges. VGPNext improves the synergy between machine and software by simplifying core functions for more user-friendly programming.

The software features a completely revolutionised graphical user interface, with a wealth of features just a click away, designed to make the operator's job easier and machine programming more practical and simpler. With “VGP Next” you can identify the part program right away, simulate the job and start production in just a few clicks.

More methods for programming the part

“VGP Next” allows customers to choose a program from the library using an archive containing images and technical data. The library collects all the programs on the server in one place, providing the convenience of preview images and numerous search filters to make this step even easier. Customised tags can be assigned to the various part programs and searches can be filtered by tag, section, material, date, machine and much more.

Importing a part program

The B_import module can be used to call up a tube or multi-tube assembly in Step or Iges formats in “VGP Next” to automatically obtain theoretical coordinates. This saves a lot of time and allows less experienced operators to quickly become familiar with the program.

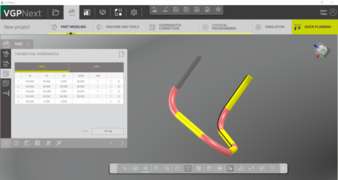

Modelling from scratch

The entire programming flow is more user-friendly with the help of a ribbon bar that assists the operator by indicating missing steps, incorrectly filled-in data, default data and user-modified data. In this way, “VGP Next” considers all possible variables – including theoretical coordinates, spring back, material elongation, bending feasibility, choice of tools, etc. – and indicates how to intervene. The operator can switch from one step to the next without losing valuable data. The 3D simulator incorporated in “VGP Next” can be used to simulate feasibility once the part has been programmed and the geometric deformations are corrected.

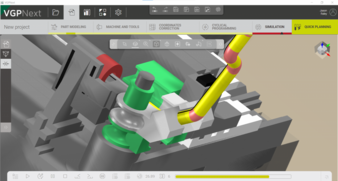

3D simulation and time estimation

“VGP Next” is equipped with a realistic simulator that anticipates potential collisions between the machined part and the machine to avoid contact and ensure safe production. Each machine is identified by its serial number, so the software knows the exact configuration of the machine and the respective accessories. This allows “VGP Next” to recognise two machines of the same family with different configurations. The simulations reflect the exact conditions of the machine and can provide even more accurate cycle time data.

Targeted defect correction

A defect correction catalogue is available in „VGP Next“ allowing the operator to conveniently select the most suitable correction without having to redesign the entire part program. The machine will then suggest which correction to make and set the parameters for the correction.

Monitoring

This function provides a complete overview of the machine’s efficiency over the entire day. It allows you to monitor the daily production of your system including checking the cycle time of the workpiece, the various completed jobs and the total number of rejects among other factors.

Plug-ins

The plug-in screen manages additional functions to simulate changes in the productivity of the system with and without a given function so that you can evaluate whether to purchase it in the future. With “VGP Next”, programming bending systems will be even easier.

For more information: https://youtu.be/u1aTvxqlgYI

BLM S.P.A.

via Selvaregina, 30

22063 Cantù (co), Italy

Tel.: +39 366 5769870

chiara.vaccari@blmgroup.it

www.blmgroup.com

“VGP Next” is part of “BLMelements”

In parallel to laser cutting systems, BLM offers a suite of native software programs that makes the most of the power of the equipment to provide users with excellent work performance and robust process features for programming both on the machine and in the office. ArTube is a BLM Group CAD/CAM software for programming lasertube systems to allow operators to draw, manipulate and design single parts or complex tubular assemblies of any section. ArTube is the most complete CAD/CAM being both dynamic and adaptable to the customer’s specific needs. ArtCut is the CAM software for 3D laser cutting cells for the programming new parts offline and starting production quickly and easily. With its immediate and user-friendly 3D graphics, ArtCut simplifies the programming of any three-dimensional workpiece and automatically solves any collisions. The cutting program simulation is remarkably true to reality. PartViewer runs a graphical simulation of cutting programs for lasertube systems and estimates execution times and costs.

ProTube is production MES, a single interface for easy and transparent management of part programs for BLM Group machines. ProTube can be used to prepare technologically precise work orders in the office, to efficiently plan production, send production orders to the connected plants and keep track of all operations. It applies artificial intelligence strategies and data interconnection with the customer's corporate ERP. ProTube is the key enabler for the evolution of smart Industry 4.0 applications.

Whatever the production context, the BLM Group has a complete range of solutions for the machining of tube, sheet metal and any three-dimensional metal profile, enhanced by dedicated software solutions and a portfolio of services that provide customers with all-around support.

About BLM Group

BLM Group is the global partner for the entire tube and sheet machining process with a capillary worldwide presence and thousands of applications:

– BLM S.p.A., based in Cantù (CO), Italy, specializes in the production of tube bending machines, tube end-forming machines, wire bending machines and 3D laser cutting cells.

– Adige S.p.A., based in Levico Terme (TN), manufactures systems for laser-cutting tubes (Lasertube) and machines for saw-cutting tubes, solids and sections with brushing, measuring, washing and collection systems.

– Adige-Sys S.p.A., based in Levico Terme (TN), specializes in the production of combined laser-cutting systems for cutting tubes and sheets and systems for laser-cutting large tubes and section profiles.