23/04/2025 – Wave spring and ring coiling machines “SNA” series

Parts with different geometries on one machine

Machines for the production of wave springs and rings – the SNA series from Wafios offers high output rates with the highest quality and thus sets standards for the highest demands.

Gears, clutches, medical devices and pumps are only some of the things that have rings and wave springs installed. While specific product requirements vary depending on the application, one thing remains constant: the demand for exceptional quality and high production efficiency. The SNA series of ring coiling and wave spring machines from Wafios sets the standard in meeting these demands.

This machine series has been consequently adjusted to the requirements of the production of wave springs and single- or multi-turn rings, made of profiled wire, with or without crimps. The SNA series offers machines for rings of 7 mm - 320 mm and wave springs of 7 mm - 250 mm outer diameter. The SNA machines achieve the highest output rates with the best quality.

A simple programming screen increases operating convenience

Preset types of rings and wave springs, defined tools and materials as well as machine settings can be easily selected via the programming system WPS 3.2 EasyWay. A main feature is the simple adjustment of geometry values, like wave height, number of waves per coil and number of coils or wave shape. The spring or ring is graphically displayed which facilitates setup. The time required to set up new parts is significantly reduced. In addition, less experienced operators are able to set up complex parts without errors.

Also the production of wave springs with varying sinusoidal waves and different wave heights is possible.

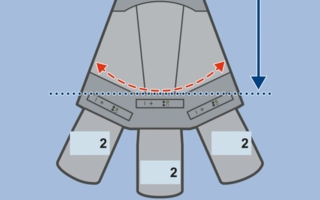

The correct cut where it is needed

The SNA machines offer different cutting techniques to achieve an optimum result. Part-specific die cuts can be made by applying the shearing and die cutting technique. Based on the machine size, also the cutting position and cutting burr can be adjusted.

Cuts can be set up in two positions. 1st position: cut from the center (4 o’clock position) and the 2nd position: conventional cut from the top (12 o’clock position).

Cutting from the center has the advantage - especially for small wave springs with a small spring index - that there are no deformations by the cut. Furthermore, the output is increased compared to cutting from the top.

However, cutting from the top enables two cutting directions by which the direction of the cutting burr can be defined.

Also, the shearing cut as well as the die cut can be used for one cutting direction. Here, the cutting unit is located on a slide that is adjustable in its height so it can be adjusted to the according outer diameter of the ring to be produced. At the same time, the cutting unit can be moved out of the coiling area when producing wave springs so there is no interference with the coiling process. For separating the wave spring from the wire, the cutting tool plunges into the wave spring.

Using iQ for achieving perfect results

The production of springs is not only facilitated by the programming system but also by the iQ functions iQwavespring and iQtorque that support the operation.

iQwavespring automatically calculates motion sequences and corrects the diameter based on variations of the pitch. The setup process is thus faster and less rejects are produced.

The iQtorque software detects workpiece as well as tool breakages and stops the machine automatically. The operator can decide whether the machine is stopped immediately or at the end of a cycle. This minimizes possible damages at the machine or tool. The individual machine axes are monitored by an envelope curve of the motor torque. Thus iQtorque can reduce downtimes and repair costs. In addition, safety is increased during unmanned automatic operation.

Interwire 2025, booth 1005

Wafios AG

Silberburgstrasse 5

72764 Reutlingen/Germany

Tel.: +49 7121 146-0

sales@wafios.de

www.wafios.com