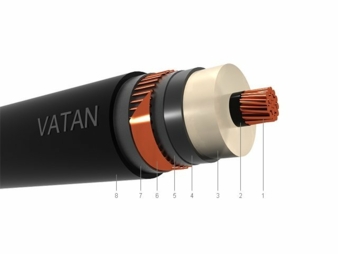

31/05/2021 – Cable production

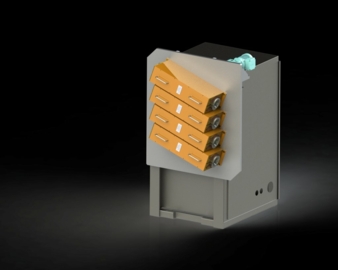

Inductive conductor preheater with automatic inductor change

GH Induction has developed a fully automated cable/conductor preheating system that avoids the risk of production losses due to human errors and greatly increases the production reliability in CCV and CVC production lines for MF and HF cables.

In this configuration, the inductors only need to be manually moved to the heating position where the conductor is located . © GH Induction

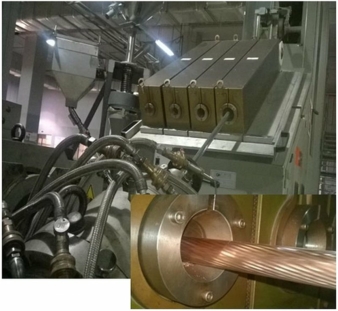

A typical conductor preheater in a production line, placed directly in front of the extrusion head. © GH Induction

In this configuration, the inductors only need to be manually moved to the heating position where the conductor is located . © GH Induction