15/09/2022 – Heat treatment

Induction tempered spring wire processing line for electric vehicles

With Radyne as part of its brand portfolio including a reference list of 20+ induction tempered (IT) spring wire lines to its merit, Inductotherm Heating+Welding Limited have responded to a market trend for a spring wire heat treatment line with handling capacity better suited for larger diameter wires, bought about by heavy Electric Vehicles (EV).

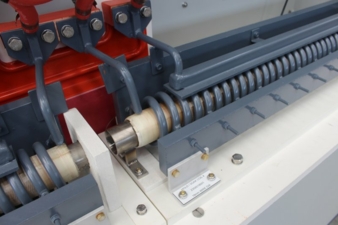

Radyne brand can now offer a turnkey equipment line that can process from 7mm up to 22mm. © Inductotherm Heating+Welding